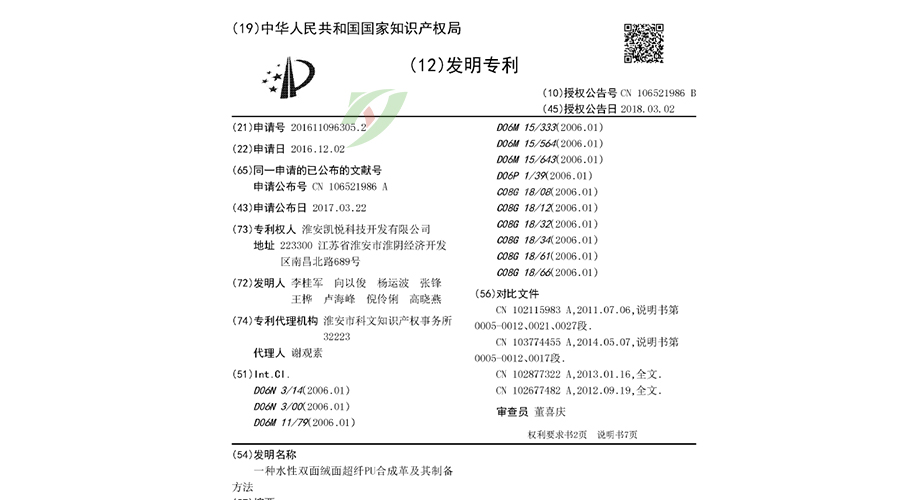

Warm congratulations to our company, Kaiyue Technology, and its parent company, Huayuan Tech, for obtaining a national invention patent authorization – (a water-based double-sided suede microfiber PU synthetic leather and its preparation method). Patent number: CN 106521986 B. Huayuan tech has a number of water-based microfiber production lines, with an annual output of 60 million meters.

The present invention mainly describes “a water-based double-sided suede microfiber and its preparation method”. The invention not only improves the production efficiency, but also does not use organic solvents in the production process, which is safe and environmentally friendly. The water-based double-sided suede microfiber produced is not only of good quality, but also completely environmentally friendly in the production process, and all indicators have basically reached international product standards after testing.

The synthetic leather industry has a history of decades of development, and with the continuous emergence of various new materials, its products are constantly being updated. The base fabric for leather is from woven to non-woven fabric, the resin used is from polyvinyl chloride, acrylic resin to polyurethane, and the base fabric fiber is also developed to microfiber. In terms of product style, artificial leather has experienced a development process from low-end to high-end, from artificial leather to overloaded leather, and some of its characteristics have surpassed natural leather. At present, the processing technology of polyurethane (PU) synthetic leather is quite mature, and people are still developing and applying new technologies, new processes and new materials to continuously improve the performance and value of products.

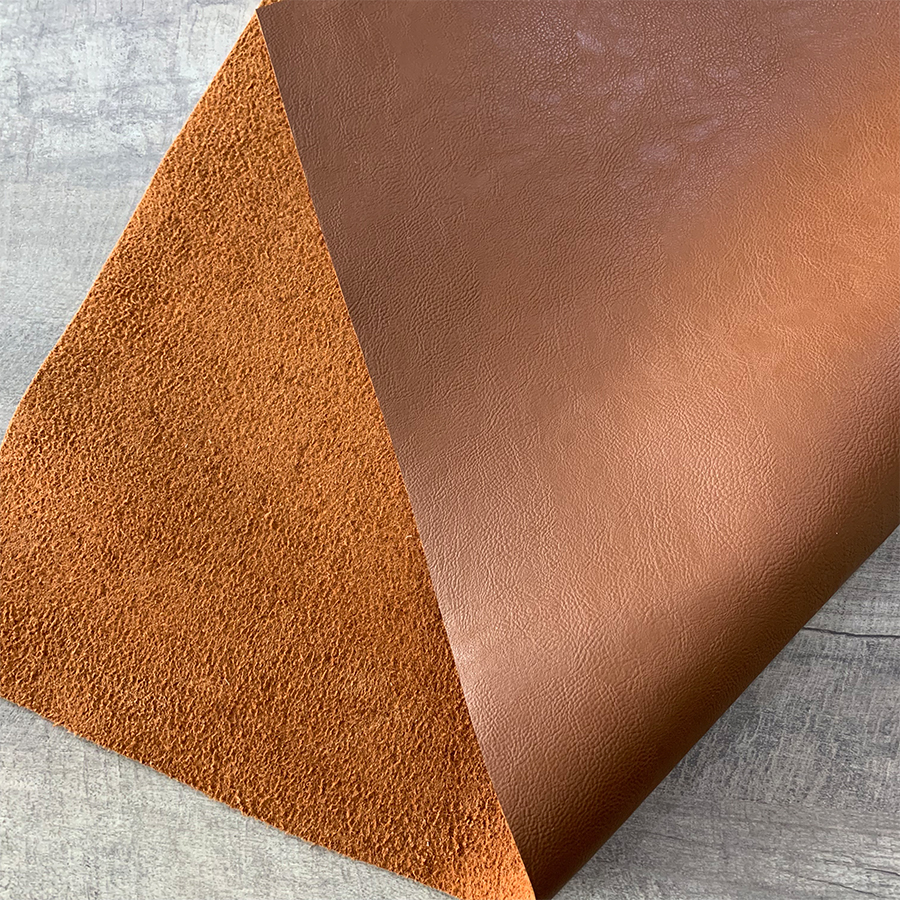

The structure of microfiber leather is very similar to that of genuine leather, both of which are three-dimensional three-dimensional structures of bundled microfibers. Microfiber synthetic leather is developed on the basis of fully dissecting natural leather. Microfiber synthetic leather is made of bundled microfiber and polyurethane through a special process. It is a non-woven fabric with a three-dimensional network structure made of nylon microfibers similar in structure and properties to bundled collagen fibers in natural leather, and has excellent refilling properties. Polyurethane with an open microporous structure is formed by post-processing Microfiber basses for post-processing.

Because microfiber leather not only has the characteristics of real leather in external performance and internal structure, but also has the convenience of industrial production and processing, the physical properties of microfiber leather products can reach or even exceed natural leather. Tearing strength, color vividness and leather surface utilization are obviously superior to natural leather, and are widely used by consumers, especially in the fields of shoemaking, luggage, clothing, furniture, home decoration, and automotive interiors. Fiber leather has become the development direction of contemporary synthetic leather.

However, the current microfiber leather preparation in my country has developed quite slowly due to technical limitations and the dependence on imported raw materials, and there are very few pure water-based and ecologically friendly microfiber leathers, and most of the conventional processes are first. Coating a surface layer and an adhesive layer on the release paper, and then laminating it with the microfiber base cloth, etc. (if a double-sided pattern is required, the above process needs to be repeated), which is not only cumbersome, but also costly. Therefore, the main water-based ecological microfiber PU leather products currently on the market mainly rely on imports.

In order to solve the above-mentioned defects of the existing technology, the purpose of this technology is to provide a water-based double-sided suede microfiber and a preparation method thereof, in order to overcome the existing problems of the current microfiber PU synthetic leather. There are problems such as complex processing technology, high cost, and mainly relying on imports.

At present, the “water-based double-sided suede microfiber leather” produced by Huayuan Hi-Tech has won the high-tech product of Jiangsu Province, breaking through the technological monopoly of Japan’s Toray Company and solving the problem that water-based microfiber mainly relies on imports.

Water-based microfiber can be widely used in automotive interiors, aircraft interiors, ship interiors, furniture decoration, luggage, shoe materials and other fields.

水性固化剂

水性固化剂

KY8770 Leather surface treatment agent,Gives leather a smooth feel

KY8770 Leather surface treatment agent,Gives leather a smooth feel

Simulation leather

Simulation leather

KY102S

KY102S

KYS 307M Waterborne Scratch resistant Matte treatment agent

KYS 307M Waterborne Scratch resistant Matte treatment agent

Water-based polyurethane foam is used to produce dry-process water-based synthetic leather

Water-based polyurethane foam is used to produce dry-process water-based synthetic leather

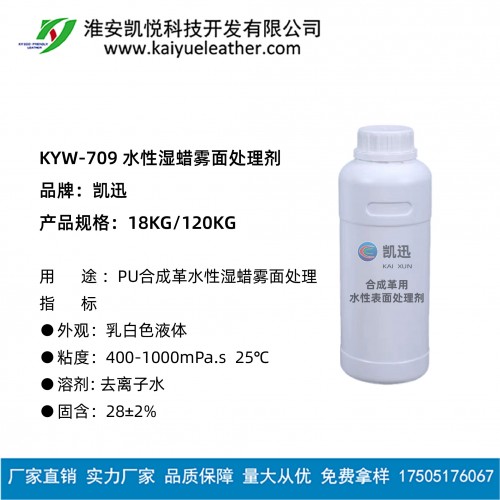

KYW-709 water-based wet wax matte treatment agent

KYW-709 water-based wet wax matte treatment agent

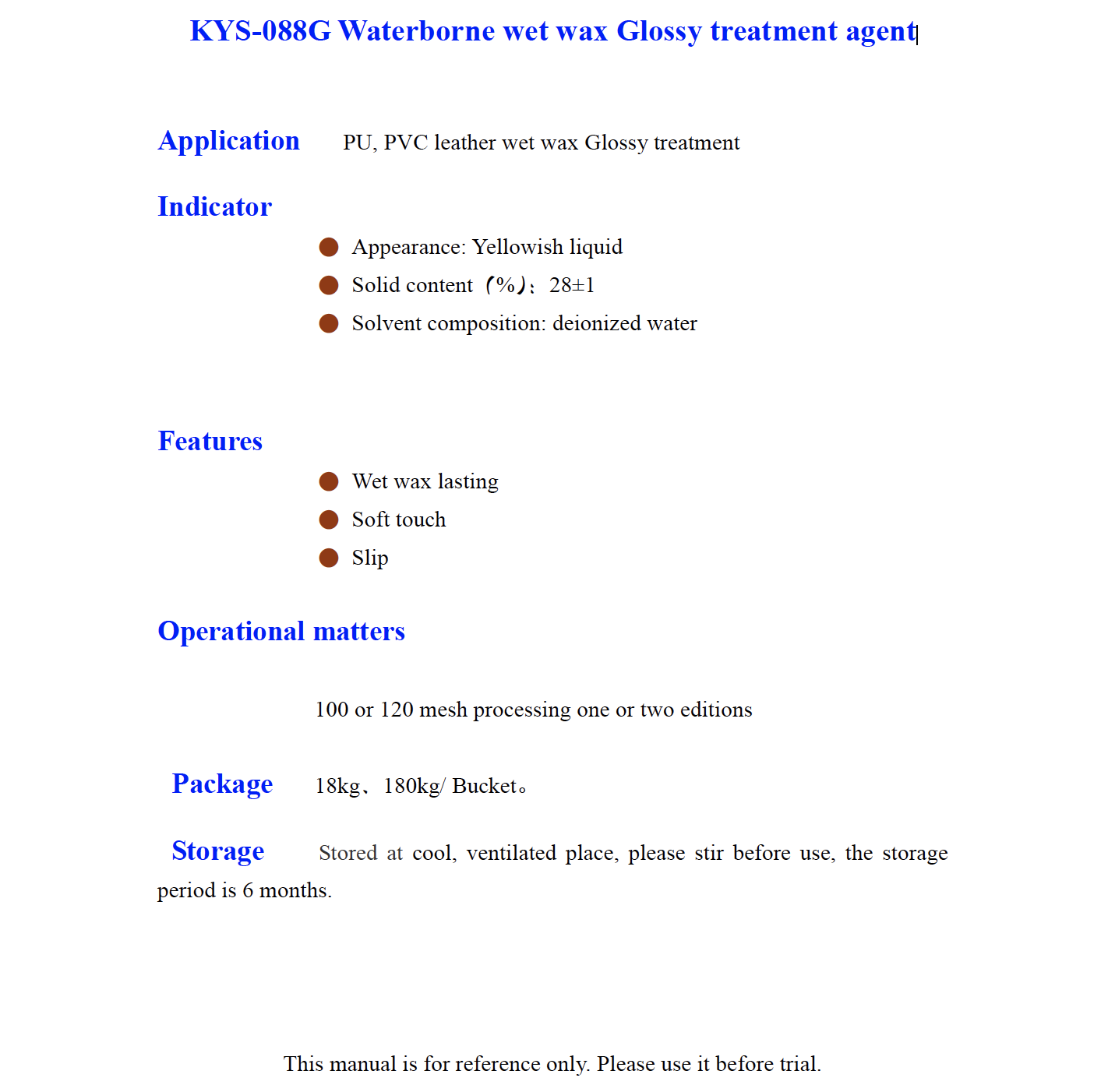

K YS 088G Waterborne wet wax Glossy treatment agent

K YS 088G Waterborne wet wax Glossy treatment agent