The 2017 China International Clothing & Accessories Fair (Autumn) will be held in Shanghai on November 11-13, 2017.

During the exhibition, a “Sustainability Zone” will be specially created, and “2017 China Sustainable Fashion Week” will be held.

One of these activities, the “5th CNTAC-ZDHC Hazardous Chemicals Control Stakeholders and Green Manufacturing Conference” was officially held in Shanghai today.

At the meeting, Deputy Secretary-General Tian Jingyan from the Artificial Leather and Synthetic Leather Special Committee of the China Plastics Processing Industry Association made a report on “National Synthetic Leather Industry DMF Emission Reduction Policy and ZDHC Standard Adoption and Implementation” report. Huai’an Kaiyue Technology Development Co., Ltd. is a member of the ZDHC Association and is committed to zero emissions of hazardous chemicals worldwide in 2020.

The report explained the “ Implementation Plan for DMF Reduction Actions in the Synthetic Leather Industry “. According to the plan, by 2020, the goal of reducing DMF usage by 25% will be achieved. The specific goals are as follows:

Control the expansion of the production capacity of synthetic leather using DMF solvent-based polyurethane resin. DMF recovery technology is a major scientific research achievement in the synthetic leather industry at the beginning of this century to strengthen environmental protection technology transformation. Anyone who uses DMF solvent-based polyurethane resin to prepare synthetic leather must fully promote closed production lines and achieve fugitive emissions on the basis of all installation of recycling devices. 100% recovery system.

Through technological transformation, the coverage of synthetic leather using water-based polyurethane resins and solvent-free polyurethanes is improved; by promoting the implementation of clean production standards, standardizing clean production processes, and increasing supervision and inspection, it is expected that after 3-5 years of technological advancement, DMF in the main processes Consumption decreased by 30%.

The following measures will be taken to achieve this goal:

1. Increase water-based and solvent-free and thermoplastic elastomers to replace DMF solvents

By the end of 2020, 10 special demonstration projects for the industrialization of artificial leather and synthetic leather for environmentally friendly materials such as water-based polyurethane resins, solvent-free polyurethanes, and thermoplastic elastomers will be completed.

The main technical measures to reduce DMF:

First, transform the dry and wet production line of synthetic leather, and use water-based polyurethane resin instead of DMF solvents to achieve zero DMF emissions;

Second, develop solvent-free polyurethane technology and equipment for preparing synthetic leather, and use solvent-free polyurethane to achieve zero DMF emissions;

Third, the development of extrusion casting process technology and equipment, through the use of thermoplastic elastomer resins including polyurethane thermoplastic elastomers, polyolefin-based non-solvent resin to produce synthetic leather, to achieve zero DMF emissions.

Huai’an Kaiyue Technology Development Co., Ltd. independently develops and produces raw waterborne polyurethane resin and waterborne PU synthetic leather. The production process is pollution-free, environmentally friendly, and does not contain harmful chemicals such as DMF and DOP.

2. Speed up the transformation and upgrading of new technology of DMF recovery system and reduce DMF emissions

At present, taking DMF end recycling and environmental treatment is still an effective measure to reduce DMF emissions. By the end of 2018, it is necessary to complete the technical transformation and upgrade of the recovery system, fully implement DMF operation in confined space equipment, and install and use pollution prevention facilities in accordance with regulations to reduce material leakage and gaseous pollutant emissions.

First, the closed-line production line was modified in the wet and dry production line, and the fugitive emissions were transformed into systematic recycling. In transportation, batching, etc., use sealed containers for transportation and promote the use of closed batching and other measures.

Secondly, carry out the development and application of workshop air purification device technology, collect the exhaust gas generated during the production process and guide the exhaust gas recovery and treatment device.

Third, the use of multi-tower recovery DMF for technological transformation and upgrading, and the establishment of DMF centralized recovery and treatment centers in industrial clusters, and comprehensive management measures for foul sources of fugitive emissions.

3.Promote DMF clean production standard system for synthetic leather and implement monitoring

The DMF reduction action plan in the field of synthetic leather is a systematic project,

First of all, we must study the planning direction of restricting and eliminating DMF, and strictly restrict new construction and expansion projects using DMF solvent-based polyurethane to prepare synthetic leather;

At the same time, the establishment of industry standards for the Evaluation System of Green Manufacturing Parks in Artificial Leather and Synthetic Leather Enterprise Clusters and the Evaluation of Green Factory for Artificial Leather and Synthetic Leather, and the improvement of DMF use control standards and technical specifications;

By promoting the implementation of clean production standards, the industry is accelerated to reduce or achieve zero DMF emissions, and control indicators are implemented in accordance with normative standards for the use of DMF.

For the industrial agglomeration areas in the synthetic leather field, it is necessary to organize the formulation of a DMF reduction action plan for the jurisdiction, and evaluate the implementation effects of synthetic leather enterprises, key processes and weak links above the designated size.

4. Fully promote advanced technologies and processes in the implementation of reduction action plans

To implement energy conservation and emission reduction, zero emissions of DMF itself need to break through cutting-edge technologies and solve key common technical problems; comprehensively promote new environmental protection materials, new processes, and intelligent high-tech technologies such as major equipment.

Encourage enterprises to actively adopt environmentally friendly new materials to produce artificial leather and synthetic leather with zero emissions, and grant 5% VAT reduction and exemption to companies that meet the National Development and Reform Commission, the Ministry of Industry and Information Technology and the Ministry of Finance’s 2016 Announcement No. 16 and have passed clean production audits to achieve Level 2 or higher .

5. Carry out green procurement and eco-label certification

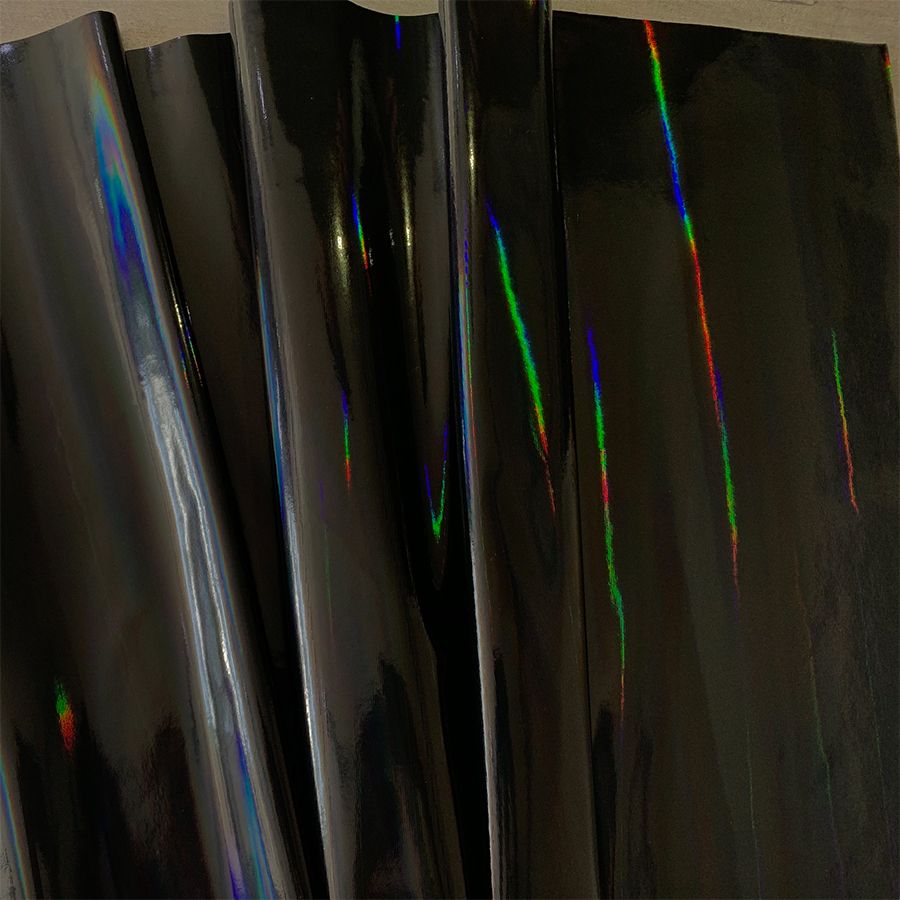

Carry out the certification and promotion of eco-synthetic leather, green synthetic leather, and fashion synthetic leather logos for consumer purchases. By starting consumers to purchase ecological synthetic leather, which does not contain DMF and zero emissions of hazardous substances, it promotes the ecological technological transformation of the industry. Promote industry certification and use eco-friendly synthetic leather and other environmentally friendly signs to promote zero DMF emissions throughout the industry. Increase the eco-synthetic leather environmental label, publicize the clean production technology of synthetic leather, and guide green consumption.

6. Step-by-step and step-by-step measures to promote zero emissions of hazardous substances

The transformation of traditional industries and the elimination of outdated technologies are a gradual process. We must not only accelerate the process of industrial ecology, but also promote steady development, stabilize the industry, and stabilize the economy.

In 2017-2018, the first round of encouragement, support, restriction, and elimination of DMF processes and lists was released by industry associations; with the encouragement and support of national policies, companies were encouraged to carry out environmental technology transformation and upgrades. From 2019 to 2020, the industry’s self-restraint and government-level policy support system will achieve the DMF reduction action target and lay a solid technical foundation for the overall achievement of the 14th Five-Year Plan.

(On-site report from “Artificial Leather Synthetic Leather Information” magazine). Please refer to the October issue of “Artificial Leather Synthetic Leather Information” for the full text of the plan.

100% Polyester-For Garments

100% Polyester-For Garments

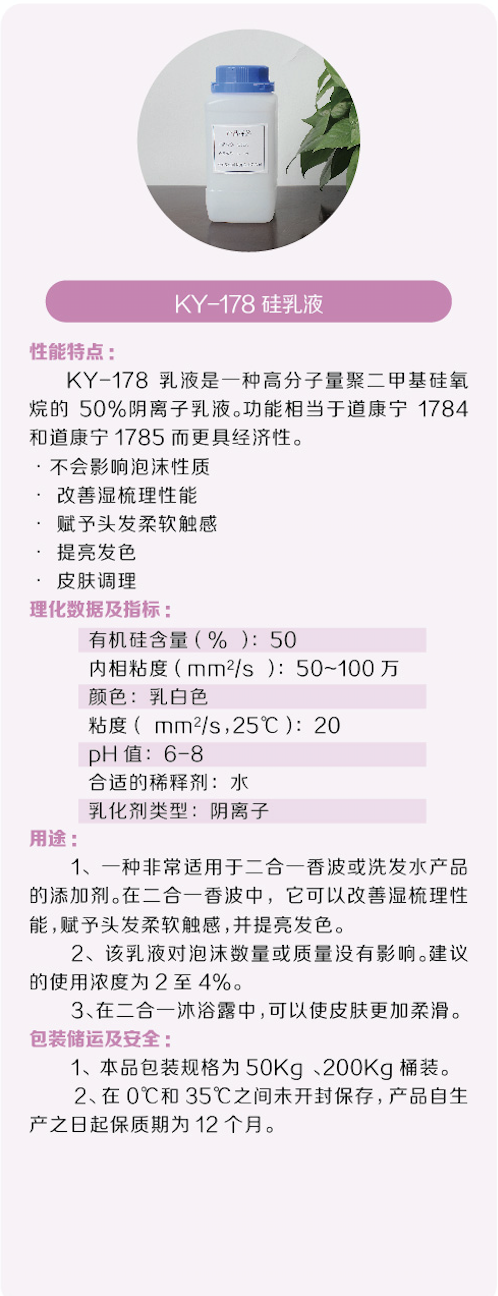

KY-178硅乳液

KY-178硅乳液

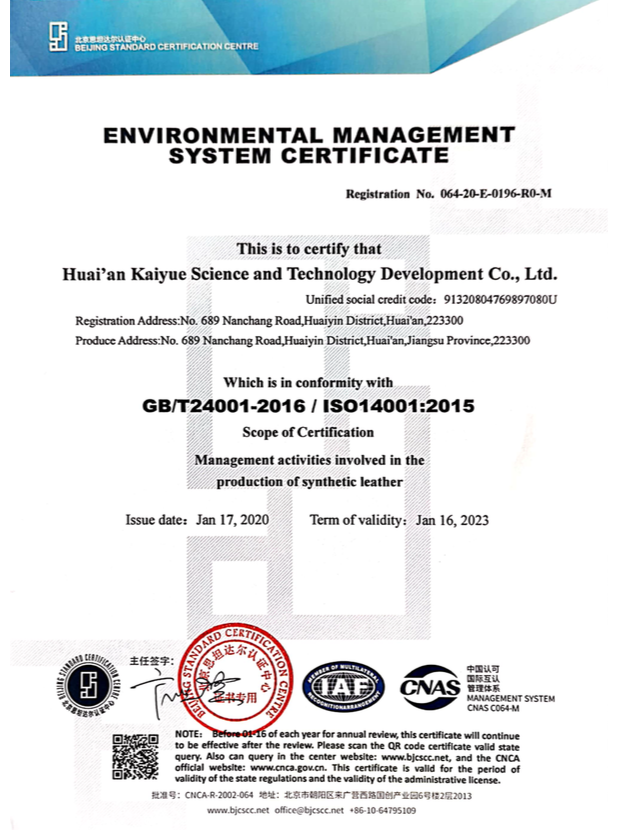

ISO14001:2015

ISO14001:2015

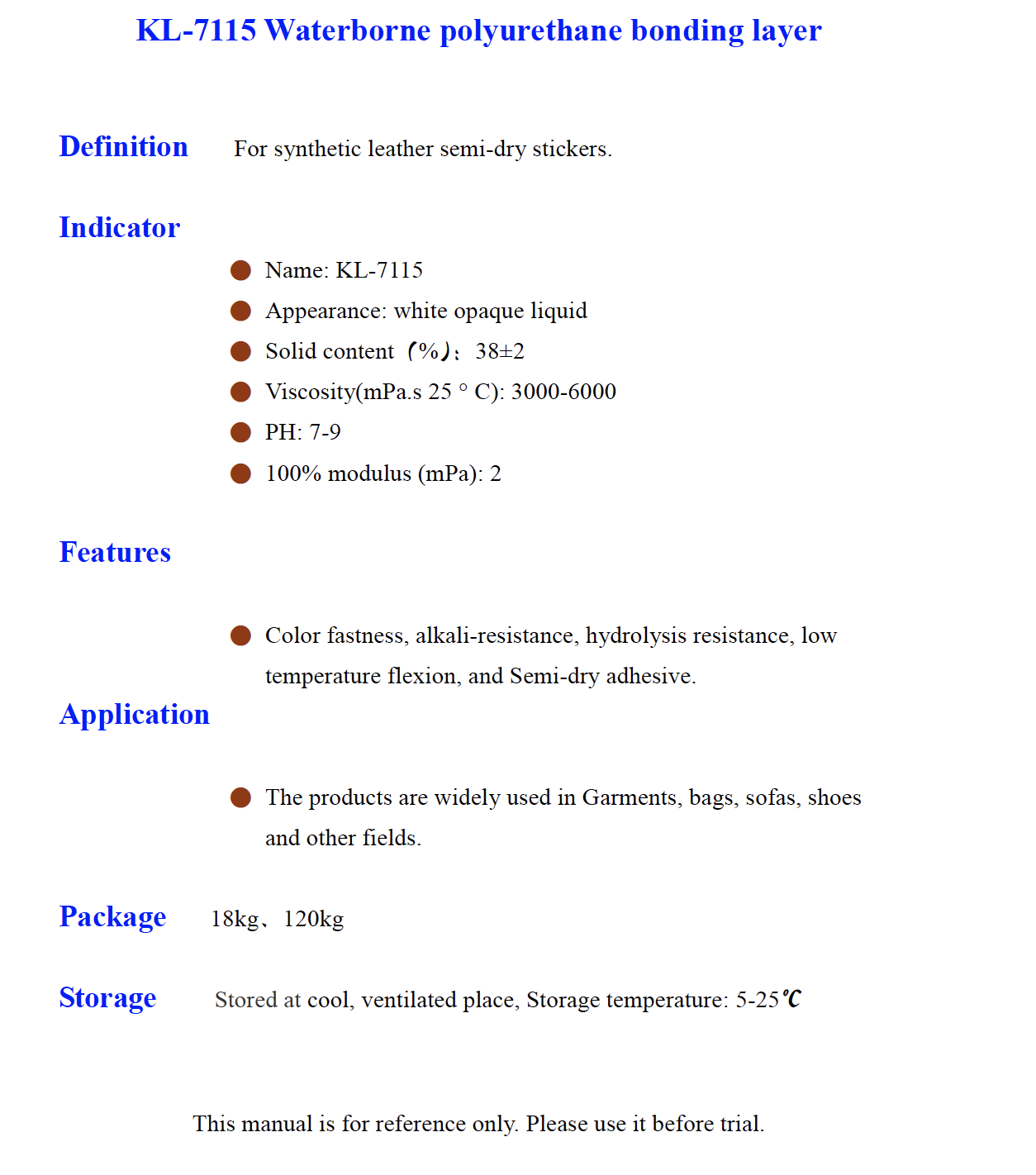

KL 7115 Waterborne polyurethane bonding layer

KL 7115 Waterborne polyurethane bonding layer

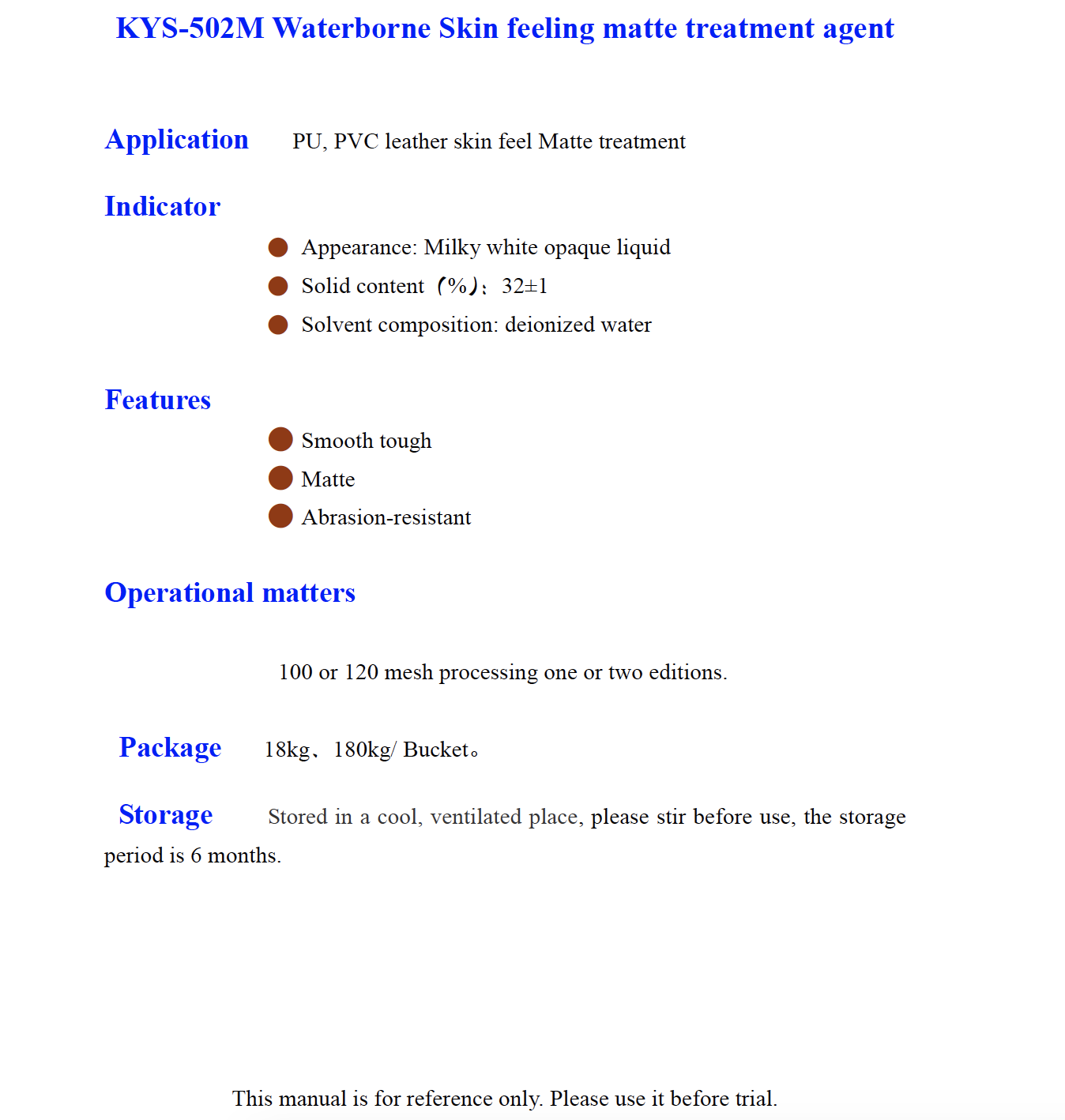

KYS 502M Waterborne Skin feeling matte treatment agent

KYS 502M Waterborne Skin feeling matte treatment agent

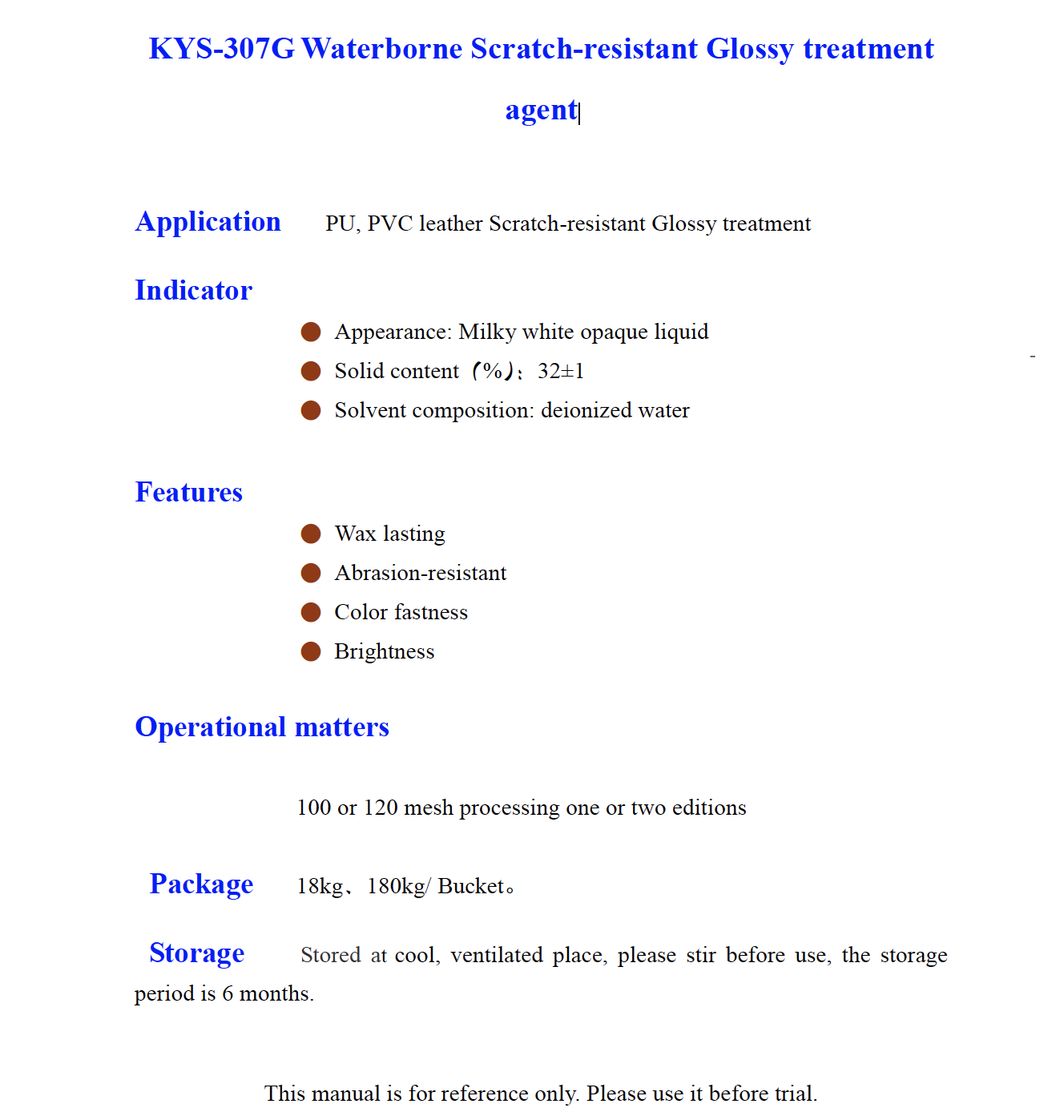

KYS 307G Waterborne Scratch resistant Glossy treatment agent

KYS 307G Waterborne Scratch resistant Glossy treatment agent

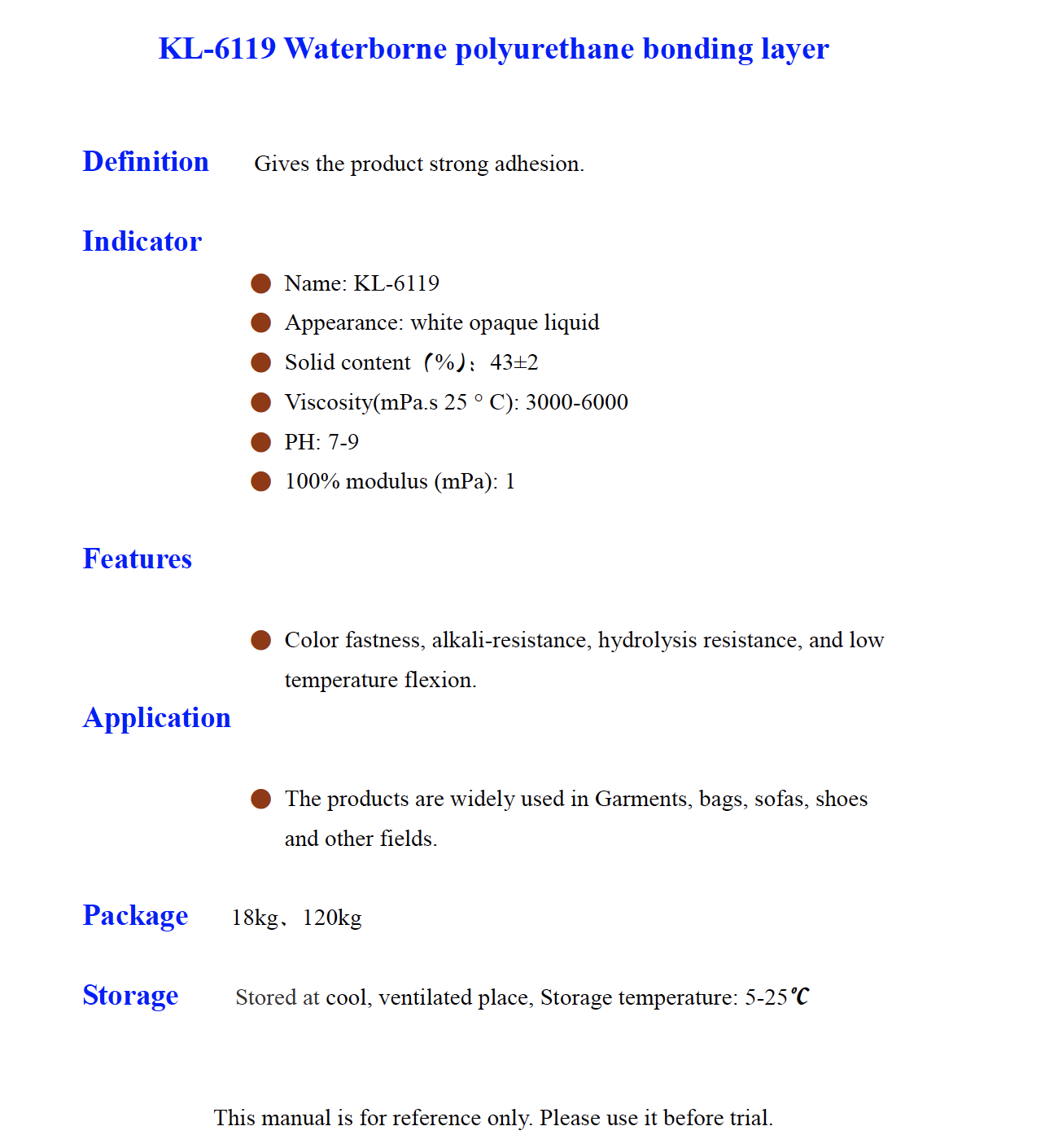

KL 6119 Waterborne polyurethane bonding layer

KL 6119 Waterborne polyurethane bonding layer

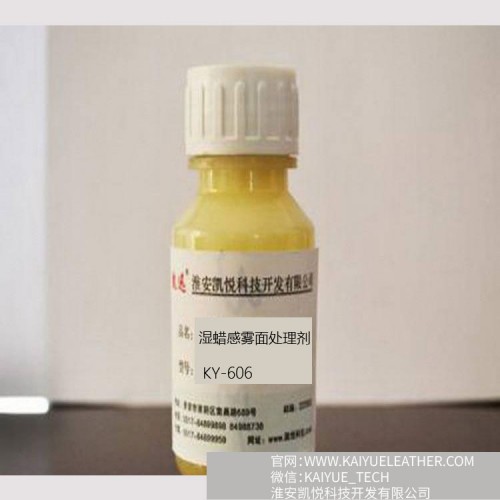

KY606 Leather surface treatment agent Wet waxy matte

KY606 Leather surface treatment agent Wet waxy matte