“Water-based coatings manufacturers have sharpened their swords in ten years, and now it should come out.” Zhu Yanan, secretary general of the China Waterborne Wood Coatings Technology Alliance, said in an interview with reporters recently. The new environmental protection policy is becoming more and more stringent, consumers’ awareness of health is increasing, and high VOCs coatings seem to be exhausted. However, according to the reporter’s understanding, in wood coatings, the water-based ratio is far below 10%. In addition to the low acceptance of downstream enterprises, the application cost and product performance of water-based coatings are still unsatisfactory. Facing the comprehensive water-based era, what are the new requirements for supporting resins, coloring systems, and additives? How should raw material manufacturers respond? The reporter conducted extensive interviews.

The chief engineer of Huai’an Kaiyue Technology Development Co., Ltd. believes that the further oil-to-water conversion of wood paints technically faces the following challenges: First, the hardness of the paint film is insufficient; The drying process is greatly affected by the environment. The reporter of China Chemical Industry News learned that most of the performance of coatings is achieved by resin. The waterborne property of wood coatings depends on the performance and cost of waterborne resin.

Different areas of furniture use have different requirements for coating performance. For example, outdoor furniture requires coatings that are resistant to water and water, and has high requirements for weather resistance and flexibility; indoor furniture has high requirements for hardness, appearance, chemical resistance, and mechanical properties. This requires targeted selection of different resin systems into the formulation design. From the perspective of resin, there are many classifications of oil-based paint resins, such as nitro paint, PU paint, UV paint, etc. Most of the resins used in wood coatings were acrylic emulsions. Although the cost is low, the drying is fast, and the sanding is good, but the performance is single and it is difficult to compare with the above oily coatings. Therefore, more water-based resin systems are needed to form the overall effect to replace the oily Resin. How to improve the performance, how to reduce the sensitivity of the paint film to the environment during the drying process, how to solve the problem of bulging, and how to improve the wettability of water-based resins to wood, all need to be solved by the resin supplier. The PUD, PUA, water-based UV, and water-based two-component systems have been successfully developed so that downstream users have more choices.

Due to the different solvents, the requirements of water-based paints on coloring systems are quite different from those of oil-based paints, which has led to the development of water-based coloring systems.

Color concentrate is a transparent coloring scheme in the coating industry. It plays an increasingly important role in the application of water-based coatings. A good water-based color concentrate not only needs to have good compatibility with water-based coatings, but also the toner used must have good fire resistance, temperature resistance, color migration resistance and sufficient vividness, and it must be solvent-based in performance. All the characteristics of the product can be better accepted by users.

At present, the transparent coloring systems for water-based systems on the market mainly include two systems of acid dyes and metal complexes. Acid dyes easily react with weakly alkaline water-based paints and are susceptible to discoloration. The previous metal complex chromogen requires the dissolution of an organic solvent, and the cost is relatively high.

Industry experts point out that colorants are also a large class of products in water-based paint coloring systems. With the hydration of coatings, the colorants that can be used with water-based coatings have great room for future development. Water-based transparent colorant is mainly used for wood coloring and topcoats of higher-grade cars. After using the transparent color paste, Gris Wood can show the wood grain well and improve the grade of wood. The use of transparent color paste with aluminum silver paste and pearlescent pigments in automotive coatings can improve the effect of automotive coatings. Water-based solid color pastes have the widest application range in water-based industrial coating coloring systems. Their performance is related to the light resistance, weather resistance, and chemical resistance of the pigment itself.

As the amount of water-based coatings continues to increase in the future, water-based coloring systems will also become more mature, providing more personalized solutions for downstream users.

It is understood that the main difference between water-based coatings and oil-based coatings lies in the solvent. Coating film formation, flow and leveling, and paint film properties are inseparably related to solvents. There are many types of solvents for oil-based coatings, and the solvents can be adjusted according to requirements. Water-based coatings only have water and a small amount of coexisting solvents. It is difficult to achieve the film-forming, flow, and leveling properties of oil-based coatings, and additives need to be adjusted.

The reporter learned that in theory, because of its higher molecular weight, aqueous emulsions can obtain better physical and chemical properties than oily systems. However, since the raw materials of the oily system have been fully developed, technical researchers can obtain ultra-high-performance coatings through special raw material selection or additives. In contrast, water-based products are not very rich, and there are no outstanding performance emulsions to choose from. It is very important to use the film-forming aids properly and to match the additives of the system to improve the film performance.

It is foreseeable that with the acceleration of the process from oil to water, a number of new film-forming aids, rheology aids, leveling agents, cross-linking agents, and functional fillers suitable for water-based coatings will emerge.

In addition, because the formulation of waterborne wood coatings contains a large amount of organic substances, it is very suitable for the growth of microorganisms. Microbial mucus will decompose the components in wood coatings, affecting the product’s fluidity and other properties, leading to product deterioration and affecting use. Therefore, it is very necessary to control the growth of microorganisms. The preservative in the tank needs to have the following characteristics: broad-spectrum antibacterial, wide range of pH, meet the protection requirements under process conditions, safe operation, good compatibility, low addition amount, and meet the requirements of relevant regulations .

KYW-709 water-based wet wax matte treatment agent

KYW-709 water-based wet wax matte treatment agent

Water-based leather surface agent, long-lasting skin feel, good haze, no hand marks KYS-502M

Water-based leather surface agent, long-lasting skin feel, good haze, no hand marks KYS-502M

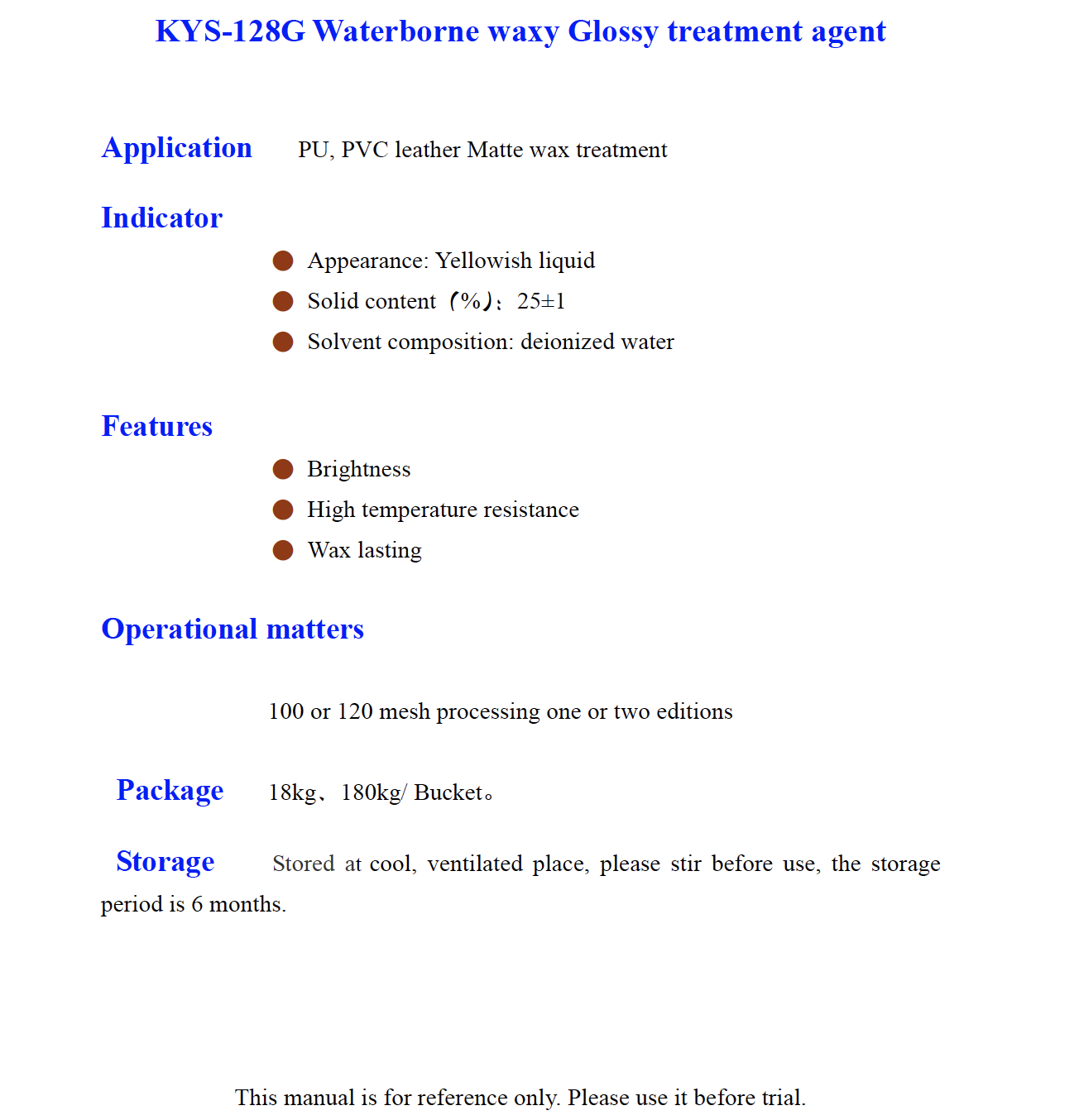

KYS 128G Waterborne waxy Glossy treatment agent

KYS 128G Waterborne waxy Glossy treatment agent

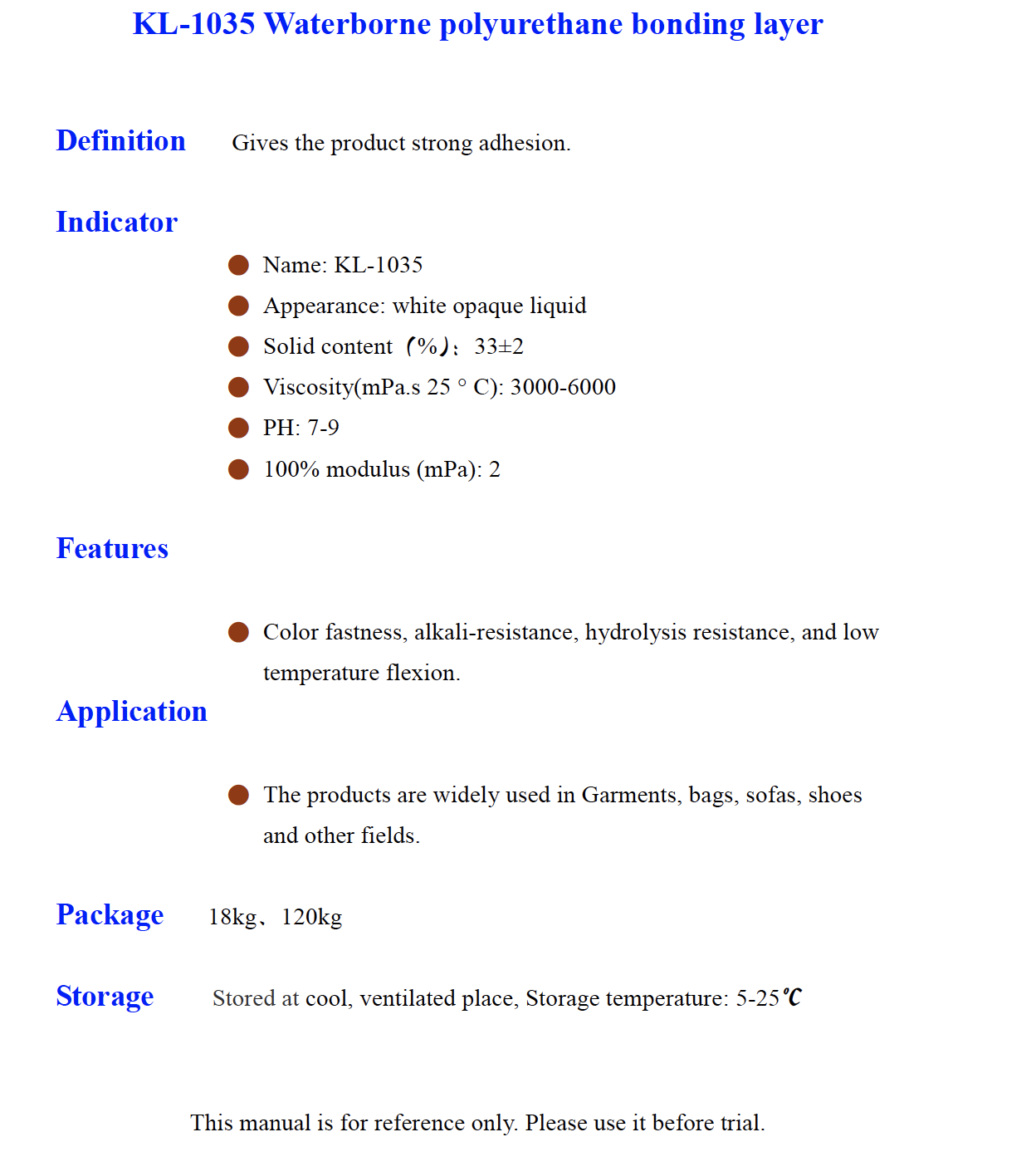

KL 1035 Waterborne polyurethane bonding layer

KL 1035 Waterborne polyurethane bonding layer

Waterborne PU leather for shoes lining

Waterborne PU leather for shoes lining

合成革用油性表面处理剂产品

合成革用油性表面处理剂产品

KX-V1100 烷芳基硅油

KX-V1100 烷芳基硅油

Waterborne PU For Handbag

Waterborne PU For Handbag