Waterborne PU resin, namely waterborne polyurethane resin, PU is the abbreviation of polyurethane in English. Waterborne PU resin is a kind of polyurethane system which uses water instead of organic solvent as dispersing medium. It is a new type of environmentally friendly macromolecule material. Waterborne PU resins are widely used as adhesives, coatings and coatings because of their excellent environmental protection, excellent mechanical properties and good compatibility with other waterborne resins.

Synthesis of waterborne PU resin:

In the synthesis of waterborne PU resin, diisocyanate, oligomer polyols and chain extender are prepolymerized firstly, and the reaction mechanism of this step belongs to step-by-step polymerization. Water-borne PU resin can be synthesized by emulsifying PU resin with certain molecular weight prepolymer or high molecular weight in water by phase transfer method.

Waterborne PU resin synthetic raw materials:

Polyisocyanates, commonly used varieties are aromatic diisocyanates, including TDI, MDI; aliphatic diisocyanate HDI and aliphatic diisocyanate IPDI, HMDI and so on. The mechanical properties of aromatic Pu are better, but due to the presence of benzene ring, it is not resistant to yellowing and its high thermal activation temperature, which limits its application range. The hydrolysis resistance and storage temperature of aliphatic or alicyclic PU are also better than that of aromatic polyurethane, and they have excellent yellowing resistance. High quality waterborne PU resins are generally synthesized by aliphatic or alicyclic isocyanates.

Macromolecular polyols: Polyether polyols, polyester polyols, polyethylene glycol, polytetrahydrofuran ether, polyesteramide, acrylic polyols and so on are the main macromolecular polyols used in the synthesis of waterborne PU resins. Among them, the ether group in polyether polyurethane is easy to rotate, has good flexibility, good low-temperature performance, and the ether group is not easy to hydrolyze, water resistance is better than polyester polyurethane. However, due to the poor hydrolysis resistance of polyester itself, the storage period of polyester waterborne polyurethane prepared from common raw materials is relatively short.

Chain extenders: small molecular chain extenders include 1,4-butanediol, ethylene glycol, adipic acid alcohol, ethylenediamine, etc. Hydrophilic chain extenders are substances that introduce hydrophilic groups while extending the chain of isocyanate-terminated polyurethane prepolymer. They are classified into anionic, cationic and non-ionic types. The commonly used are dihydroxymethylpropionic acid (DMPA), sodium ethylenediamine sulfonate and diethylenetriamine. Methyl diethanolamine, etc. These structures usually contain carboxyl, sulfonic or secondary amino groups. When the side chains are attached to the polyurethane molecular chain, the functional groups can be ionized on the PU chain.

Neutralizer: also known as salting agent, reagent that can react carboxyl and sulfonic groups to form polymer salts or ionic groups. The neutralizers used in anionic waterborne PU mainly include triethylamine, ammonia, sodium hydroxide, etc. The neutralizers used in cationic waterborne PU mainly include acetic acid, CH3I, epichlorohydrin, etc.

Solvent: The commonly used solvent is acetone, because the viscosity of water-borne PU will increase in the reaction process, leading to stirring difficulties, inadequate reaction, adding acetone to reduce the viscosity, conducive to stirring to make the reaction full. The boiling point of acetone is low. After synthesis, acetone in water-borne PU can be removed.

Performance advantages of waterborne PU resin:

1. Because the dispersing medium is water, it is non-toxic, non-flammable, non-polluting, energy-saving, safe and reliable. Transportation safety, good working environment. The system does not contain toxic – NCO group, the product has no residual toxic solvents, and the product is safe and environmentally friendly.

2. Water-borne PU resin has much better moisture permeability and air permeability than solvent-based PU products, because water-borne PU resin has strong hydrophilicity, so it has strong binding ability with water, and the product has good moisture permeability and air permeability.

3. Water as a continuous phase makes the viscosity of waterborne polyurethane system independent of the molecular weight of polyurethane resin, and lower than solvent-based PU with the same solid content. It is easy to process and operate.

4. waterborne PU resin system can be blended with other waterborne emulsion or copolymerized to blend, which can reduce cost or obtain more diversified and superior PU emulsions.

5. Waterborne PU resin has good film-forming performance, firm bonding, cold resistance, water resistance, solvent resistance and wear resistance. Because of its adjustable softness and hardness, the application field of waterborne PU resin has been greatly broadened. Hard waterborne PU can be used as waterborne floor paint, waterborne wood paint, soft waterborne PU can be used as soft coating finishing of fabrics and so on.

Application fields of waterborne PU resins:

Material Composite: Adhesive Composite of PVC, PP, ABS, XPE, PU, PET, wood, cloth, paper and other materials;

Automobile interior glue: automobile interior glue (door panel, dashboard, armrest, etc.) and automobile interior flocking glue (storage box, sealing strip, backup tire cover, etc.).

Flocking glue: It can be used for electrostatic flocking on various plastics (PVC, ABS, PU…), sponges, metal parts and other materials.

Vacuum Absorbing Plastics: Polyvinyl chloride (PVC) and other soft materials and vacuum forming of density boards, particleboard, wood, etc., used in paint-free doors, cabinets, computer tables, speaker boards, etc.

Coatings, such as metal, glass, stone, wood, rubber, plastic, fabric, etc., are used as metal, glass, stone and other coatings to enhance the surface properties, such as surface enhancement, brightening, abrasion resistance, aging resistance, solvent resistance, corrosion resistance, high temperature resistance, acid and alkali resistance, etc. As a fabric finishing, it can play the roles of soft and comfortable handle, waterproof, breathable and moisture permeable, bright and beautiful color, wrinkle-proof, shrink-proof and pilling-proof.

Water-based scratch-resistant matte treatment agent

Water-based scratch-resistant matte treatment agent

KX-0065 Polyether modified silicone oil

KX-0065 Polyether modified silicone oil

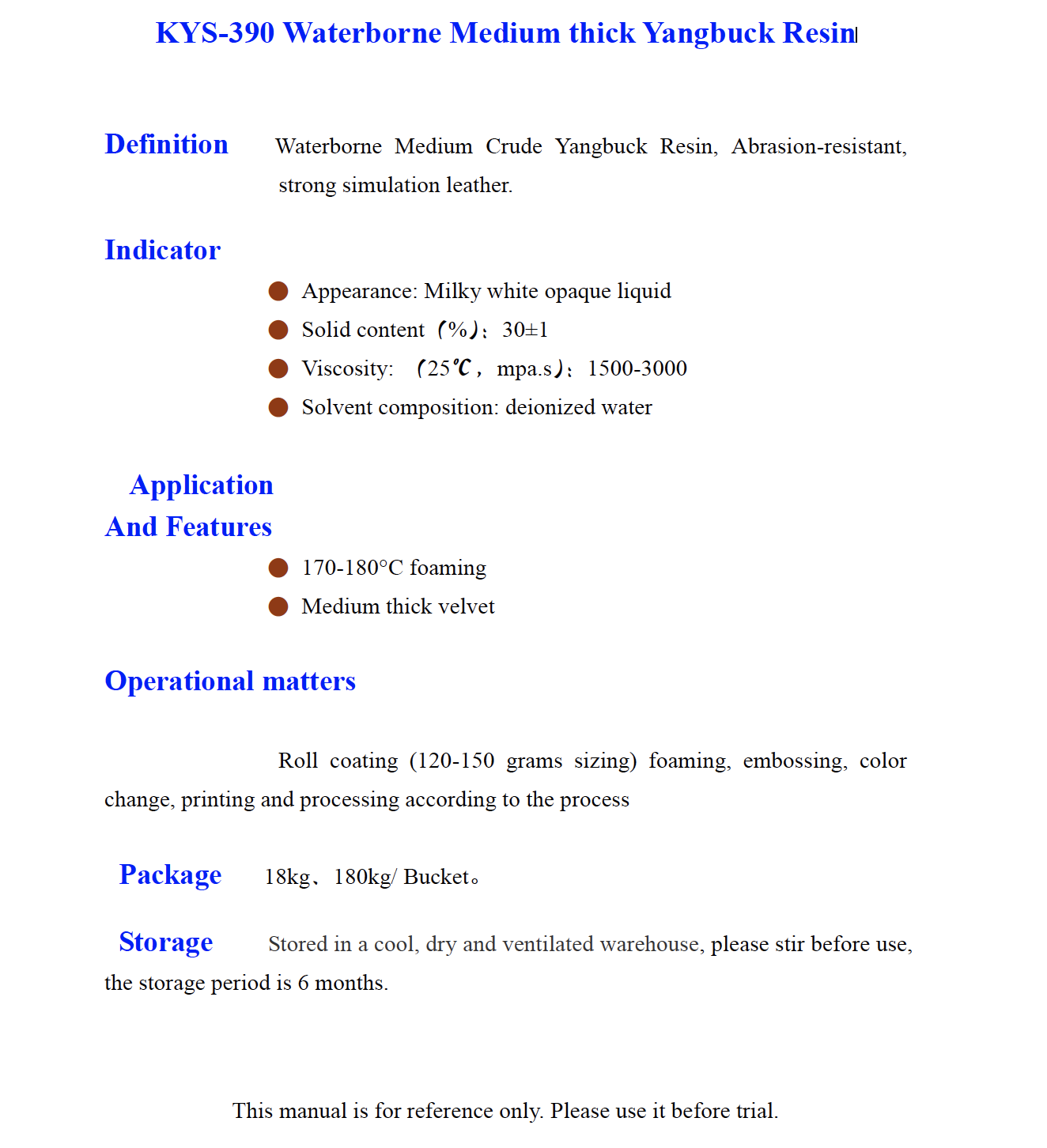

KYS 390 Waterborne Medium thick Yangbuck Resin

KYS 390 Waterborne Medium thick Yangbuck Resin

Waterborne PU leather (Crazy horse)

Waterborne PU leather (Crazy horse)

KY102S

KY102S

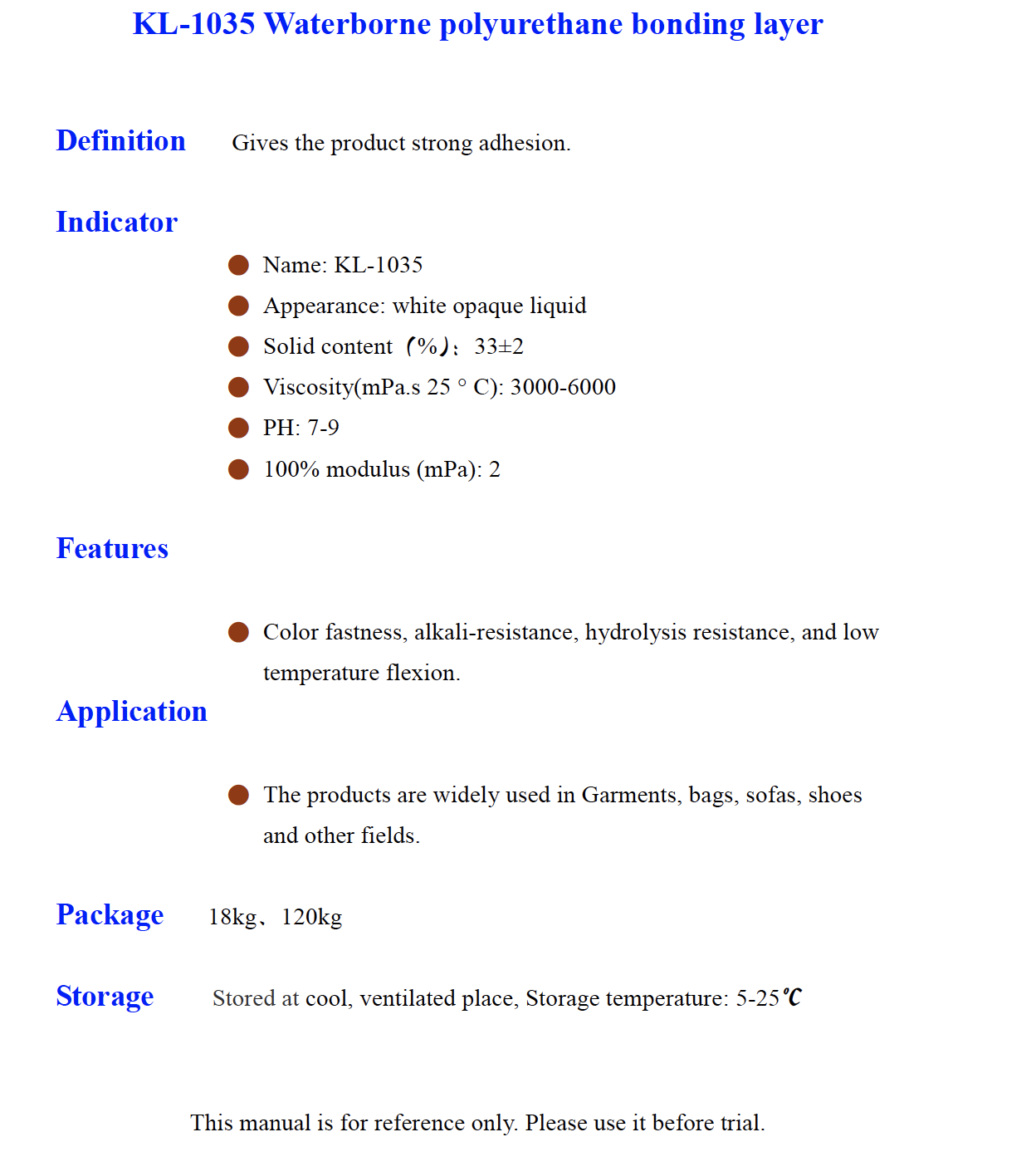

KL 1035 Waterborne polyurethane bonding layer

KL 1035 Waterborne polyurethane bonding layer

100% Polyester-For Garments

100% Polyester-For Garments

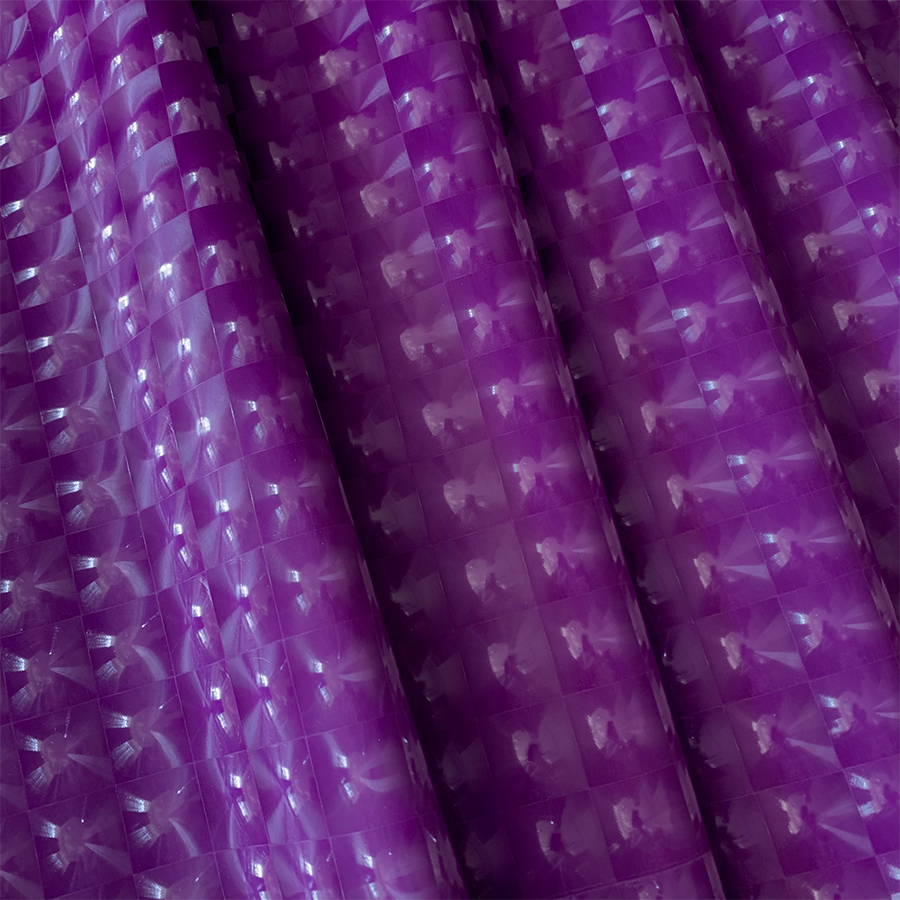

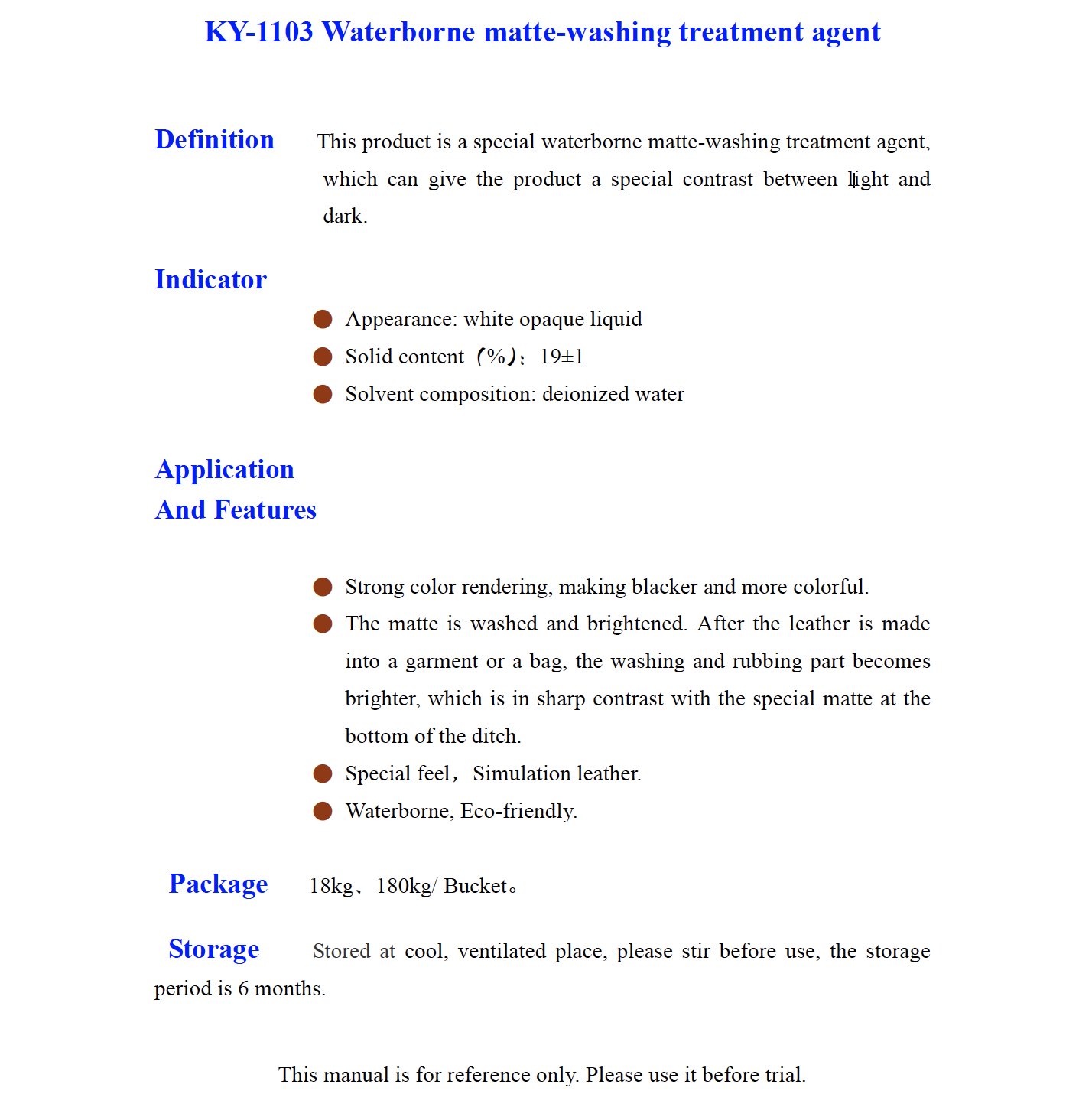

K Y 1103 Waterborne matte washing treatment agent

K Y 1103 Waterborne matte washing treatment agent