Question: What is waterborne PU leather?

Waterborne(Water-based) PU leather is called waterborne polyurethane synthetic leather. It is a synthetic leather made of waterborne polyurethane and does not contain toxic organic solvents. It is the latest replacement product of traditional solvent-based synthetic leather and a product that conforms to the sustainable development of the world. There is no pollution in the production process, no toxic or harmful waste gas and waste-water discharge. It does not contain DMFa, DMFu, o-benzenes, PAHs, APEO, azo, BPA, formaldehyde, heavy metals, and other harmful chemicals. It is healthy, environmentally friendly, and truly harmless to the body. It can meet the latest environmental protection standards of REACH, ZDHC, OKEO-TEX Standard 100 and GRS, etc, can meet the highest environmental protection requirements for synthetic leather.

Q: What is DMF? What is DMF-FREE leather?

The full name of DMF is Dimethyl Formamide, which is a very versatile chemical raw material and is widely used in the production of traditional solvent-based PU leather. DMF is moderately toxic, irritating to the eyes, skin, and respiratory tract. After invading the body, it is mainly metabolized in the liver, and it also causes damage to the kidneys.

On October 27, 2017, the World Health Organization,International Agency for Research on Cancer declared DMF as a category 2A carcinogen. Recently, the European Union identified DMFa and DMFu as special substances that affect fertility and are banned in products for children under 16 years of age.

Waterborne PU leather can also be called DMF-free leather, which is a new type of composite material, it is environmentally friendly, non-toxic, harmless to the body, and has high performance.

Q: What is the difference between waterborne PU leather and solvent-based PU leather on the market?

To figure out what is waterborne PU synthetic leather, firstly we must figure out the classification and structure of synthetic leather.

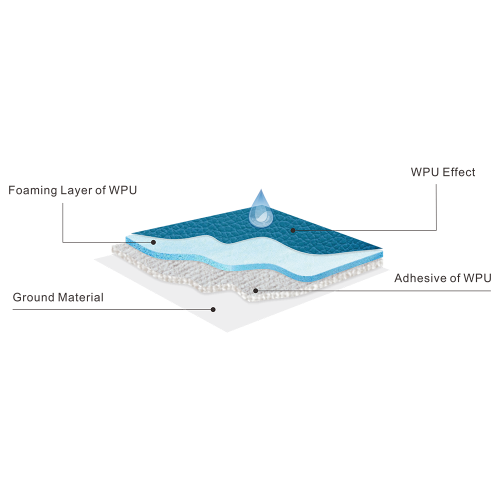

PU synthetic leather is divided into dry method PU and wet method PU. Dry method PU leather is composed of a four-layer structure of the base fabric, adhesive layer, surface layer, and surface treatment layer, while wet method PU leather is composed of five layers of the base fabric, adhesive layer, foam layer, surface layer, and surface treatment layer. Structural composition, wet method PU leather has one more foam layer than dry method PU leather. Traditionally, the adhesive layer, foam layer, surface layer, and surface treatment layer are all made of polyurethane chemical materials containing toxic solvents such as DMF. By contrast, waterborne PU leather is made of waterborne polyurethane as raw material, using water instead of DMF and other toxic solvents.

On the surface, it seems that toxic solvents such as DMF in chemical materials have been replaced with water, from the perspective of scientific research, huge changes have occurred in many aspects, such as raw material selection, patent formulation, process, equipment selection, etc. Compared with traditional solvent-based PU leather on the market, waterborne PU leather is harmless, non-toxic, and odorless. There also reduces energy consumption in the production process and has no toxic and harmful waste-gas or waste-water discharge. Therefore, waterborne PU leather can fully meet the highest international environmental protection requirements for synthetic leather.

Waterborne PU leather also has excellent physical properties, high peeling resistance, high folding resistance, high abrasion resistance, etc. It is the best substitute for genuine leather and traditional solvent-based synthetic leather. It’s the designated leather for developed countries such as Europe, America, and Japan.

Question: Which is better than waterborne PU leather or animal leather?

In response to this problem, here is a factual case.

One of the most destructive confusions in the fashion circle is the belief that “leather is just a by-product, and if it is not used, we must discard it. Using leather is just waste utilization.” Many people stick to this idea as a reasonable explanation for the misfortune of cattle, sheep,and even rare animals. But unfortunately, this is not the case. People’s demand for leather has already exceeded the amount of leather brought by the meat. So in some cases, the order should be reversed, “Leather is not a by-product of meat, but meat is a by-product of leather.” With the voices of “anti-fur” and “zero cruelty”, the concept of responsible consumption has become more popular, more and more brands and companies have begun to abandon leather and fur to choose other alternative materials.

As the latest technological products, waterborne PU leather and waterborne microfiber synthetic leather made of waterborne polyurethane have ultra-high physical properties and strict chemical standards. It has high abrasion resistance, high folding resistance, high cold resistance, etc. DMF free, VOC (volatile organic compounds) free, etc. Thereby reducing pollution, improving resource utilization efficiency, reducing resource consumption, reducing or eliminating safety risks and hazards to human health and the environment. Its non-toxic, harmless, green and environmentally-friendly product performance fully meets the import standards of artificial leather and synthetic leather in developed countries such as Europe and the United States.

Regarding the question of whether waterborne synthetic leather is better or animal leather, everyone must have an answer in their minds. Fashion ≠ animal leather, fashion needs to conform to the sustainable development of the world.

Question: Does water-based PU leather belong to Vegan leather?

Yes, water-based PU leather does not contain any animal skins,and does not use any toxic or harmful chemical solvents. It is completely healthy and environmentally-friendly vegan leather.

Q: What are the advantages and disadvantages of Italian Vegan Leather compared to your waterborne PU leather?

Italy’s Vegan Leather (such as grape leather) has strong marketing campaigns, but it is not actually available and cannot be mass-produced. The waterborne PU leather is based on a large number of scientific patents and has actual products that can be mass-produced to meet the huge market demand. It is synthetic leather that does not contain animal skin ingredients and does not contain harmful chemicals such as DMF.

Q: Is waterborne PU leather sustainable?

Yes.

What is sustainable development?

Sustainable development can be defined as development that meets the needs of the present without compromising the ability of future generations to meet their own needs.

Using waterborne PU leather is equivalent to protecting the environment

The fashion industry, furniture industry, and many other industries need to use a lot of synthetic leather every year, but traditional PU synthetic leather is made by using DMF as the solvent. The process will release toxic gases and discharge large amounts of toxic solvents. These waste-gas and waste-water flow into nature, causing pollution to the environment and harm to the human body.

However, the waterborne PU synthetic leather produced by waterborne resin is environmentally friendly and pollution-free in the production process, no toxic and harmful industrial waste-gas or waste-water is discharged, and no toxic substances remain in the finished product, which can fully meet the highest international environmental protection requirements for synthetic leather.

Using waterborne PU leather can maintain ecological balance

Skins of animals are peeled alive, and real leather is used to make clothes, shoes, bags, etc. It is cruel and destroys the ecological balance. A large number of illegal hunting has caused many rare animals to be on the verge of extinction. The use of synthetic leather can reduce damage to animals.

In summary, the use of waterborne PU leather satisfies sustainable development and meets the needs of present people for fashion while protecting the environment without compromising the ability of future generations to meet their own needs.

Q: What fields can waterborne PU be applied to?

Waterborne PU leather can be applied to shoes, bags, furniture, clothing, packaging, home decoration, sports goods, etc.

Q: What are the physical properties of waterborne PU leather?

We can produce waterborne PU leather of corresponding standards according to the different physical requirements of each field. It has the properties of breathability, abrasion resistance, scratch resistance, folding resistance, and peeling resistance. If you have special requirements, you can also customize waterborne PU leather with waterproof, flame-retardant, anti-mildew, and anti-ultraviolet, etc.

Q: What is waterborne microfiber synthetic leather? Is it waterborne PU leather?

Waterborne microfiber synthetic leather belongs to high-end waterborne PU leather. Microfiber synthetic leather is developed on the basis of analyzing animal skins. Its structure is similar to animal skins, and its characteristics even surpass natural leather. With extremely excellent abrasive resistance, excellent cold resistance, breathability, and aging resistance, it is praised and favored by leather goods designers.

Question: What is the chemical standard of waterborne PU leather?

Waterborne PU leather does not contain DMFa, DMFu, o-benzenes, PAHs, APEO, azo, BPA, formaldehyde, heavy metals and other toxic and harmful chemicals, and can meet ISO, REACH, RoHS, OEKO-TEX, GRS and other certification standards.

Question: Does your factory have a certificate for waterborne PU?

Yes, our factory has ISO45001, GB/T24001/ISO14001,

GB/T19001/ISO9001, GRS, and other certifications.

Our products have inspection reports from authoritative testing organizations such as SGS, BV, and the company is equipped with complete physical and chemical testing equipment to ensure that each batch of water-based products fully meets the highest environmental protection requirements.

Question: Is waterborne PU leather your patented product?

Waterborne PU leather is new technology-based material. Our company has more than 100 patents for waterborne polyurethane inventions, waterborne synthetic leather innovative technology and preparation patents, and waterborne synthetic leather production line equipment patents. The company has the world’s leading waterborne polyurethane technology and is a full-material supplier of water-based synthetic leather technology solutions in the industry.

Question: There are many water-based PU leather on the market, how to distinguish authenticity?

Waterborne PU technology and waterborne microfiber technology are currently only mastered by a very small number of companies, and the market demand is huge, counterfeit “water-based” products will appear on the market. When purchasing, look for products produced by formal factories. A formal factory should have the National Development and Reform Commission’s waterborne PU project approval, the State Environmental Protection Agency’s environmental assessment report, and the State Administration for Industry and Commerce project registration. Water-based PU leather has no pungent odor, no harmful chemicals. It also can be identified by the chemical test report from SGS, BV, and other institutions.

Consumers can choose water-based PU leather based on the above points.

Question: What are your advantages over other waterborne PU leather factories?

Waterborne PU technology and waterborne microfiber technology are currently only mastered by a few companies. Our company has more than 100 patents for waterborne polyurethane inventions, water-based synthetic leather innovative technology and preparation patents, and water-based synthetic leather production line equipment patents. Our company has the world’s leading waterborne polyurethane technology. It is the industry’s leading supplier. From the core material-waterborne resin to waterborne surface treatment agents, waterborne functional additives, waterborne synthetic leather BASE to waterborne synthetic leather products, the whole process is self-controlled. Therefore, we have an absolute price advantage, a rich product line, short research and development cycle, and products with special performance can be customized. We have a complete sales system and after-sales service to provide the market and brands with the highest quality waterborne PU leather.

Q: What is GRS? Do you have GRS products?

A: The Global Recycle Standard (GRS) was originally developed by Control Union Certifications (CU) in 2008 and ownership was passed to Textile Exchange on January 1, 2011. The Global Recycled Standard (GRS) is an international, voluntary, full product standard that sets requirements for third-party certification of Recycled Content, chain of custody, social and environmental practices, and chemical restrictions. The goal of the GRS is to increase the use of recycled materials in products and reduce/eliminate the harm caused by its production.

The Global Recycled Standard is intended for use with any product that contains at least 20% Recycled Material. Each stage of production is required to be certified, beginning at the recycling stage and ending at the last seller in the final business-to-business transaction. Material Collection and Material Concentration sites are subject to self-declaration, document collection, and on-site visits.

More and more major international brands prefer selecting supplier which have GRS certification as a condition. By recycling the recyclable renewable fiber raw materials during the production process and after use, and then making clothing, luggage, a series of GRS certified products are also favored by consumers and brands. Our company has passed GRS certification and can provide waterborne PU leather products using recycled polyester as the leather base fabric.

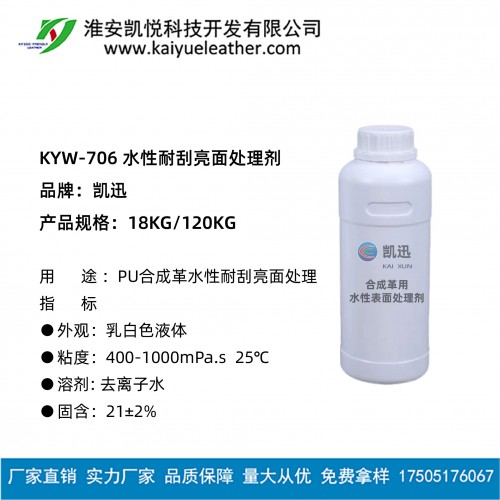

Water-based scratch-resistant matte treatment agent

Water-based scratch-resistant matte treatment agent

Microfibre

Microfibre

Suede/TC for Garments III

Suede/TC for Garments III

KX-388 waterborne leather additives

KX-388 waterborne leather additives

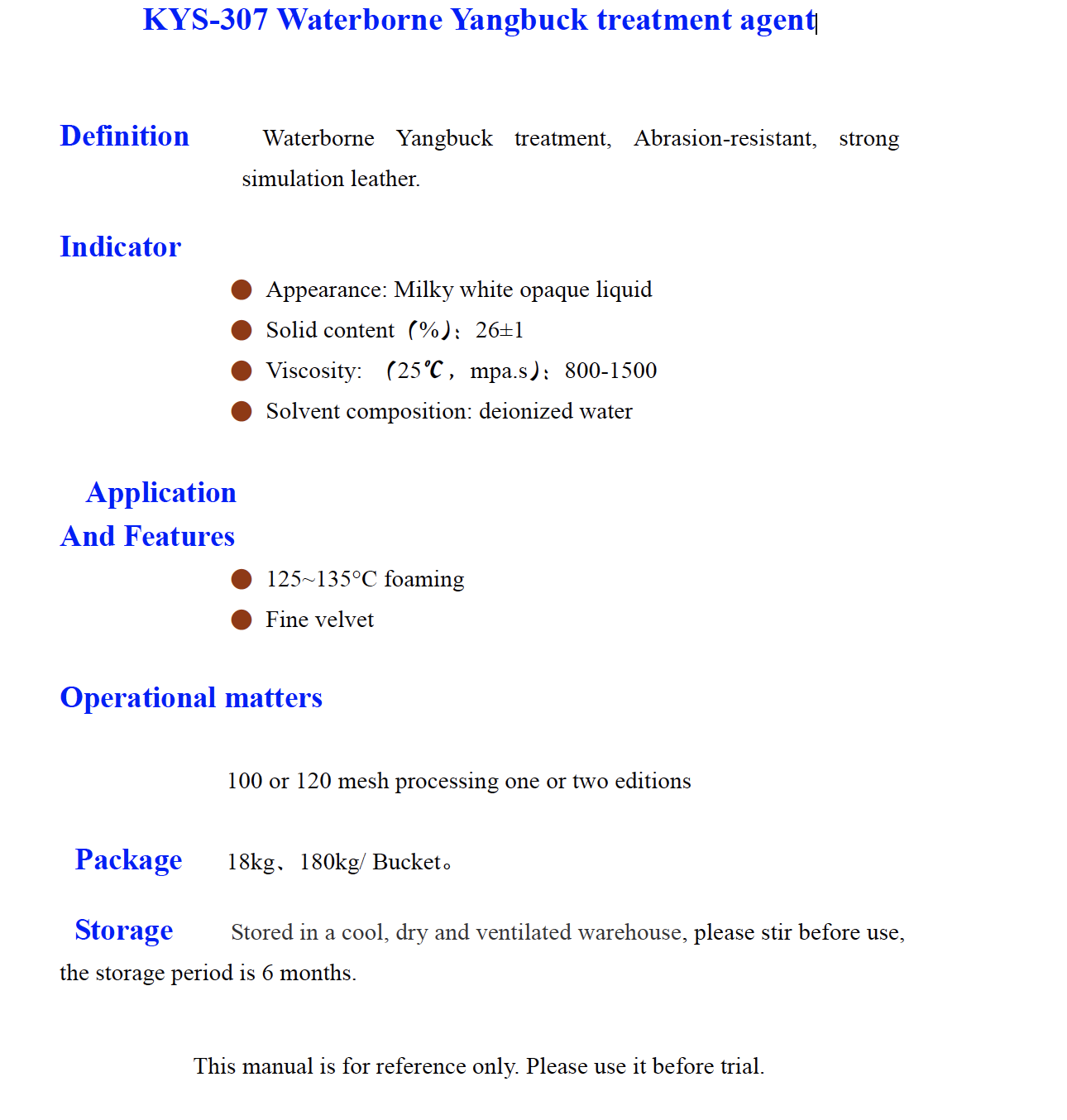

KYS 307 Waterborne Yangbuck treatment agent

KYS 307 Waterborne Yangbuck treatment agent

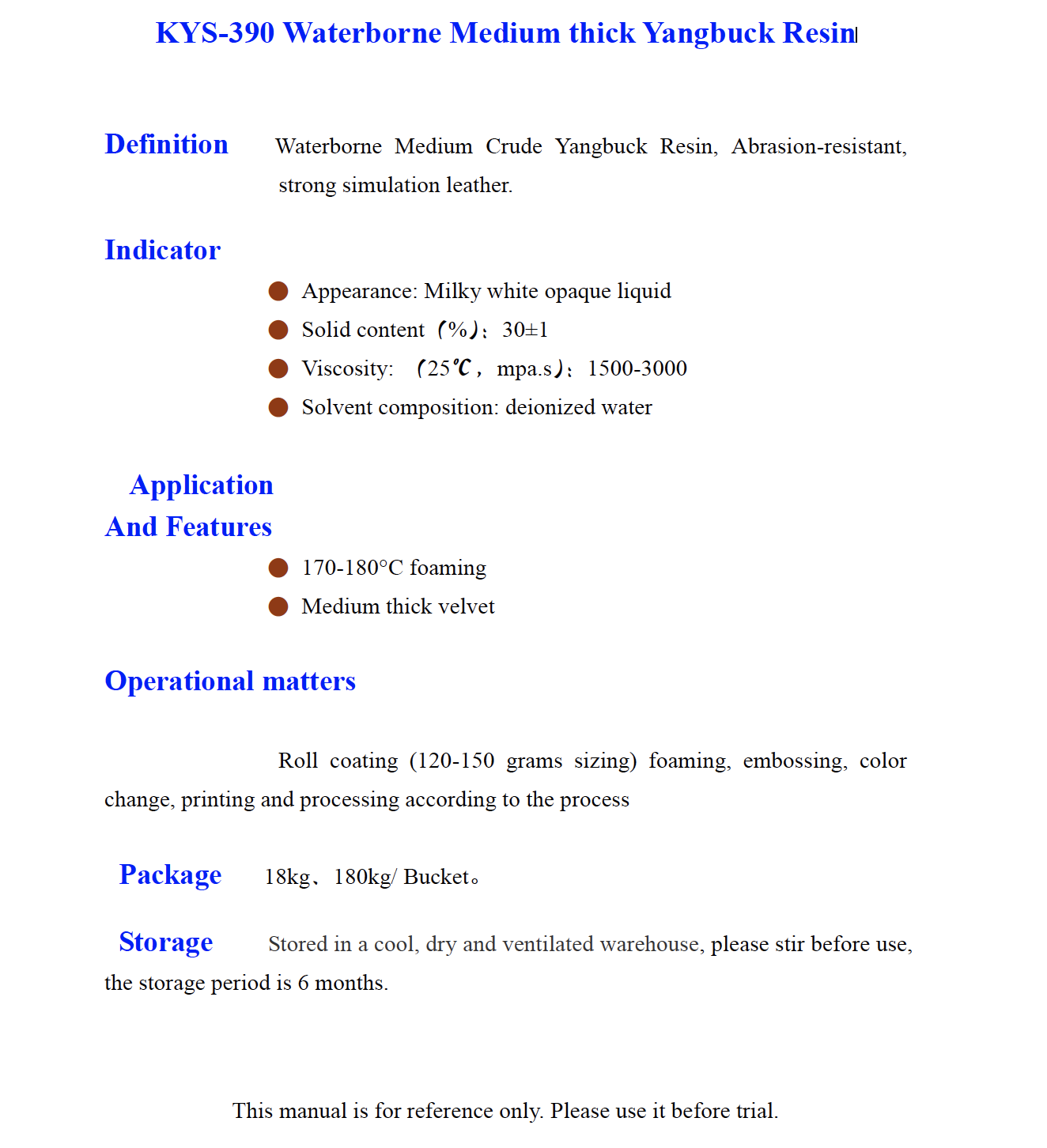

KYS 390 Waterborne Medium thick Yangbuck Resin

KYS 390 Waterborne Medium thick Yangbuck Resin

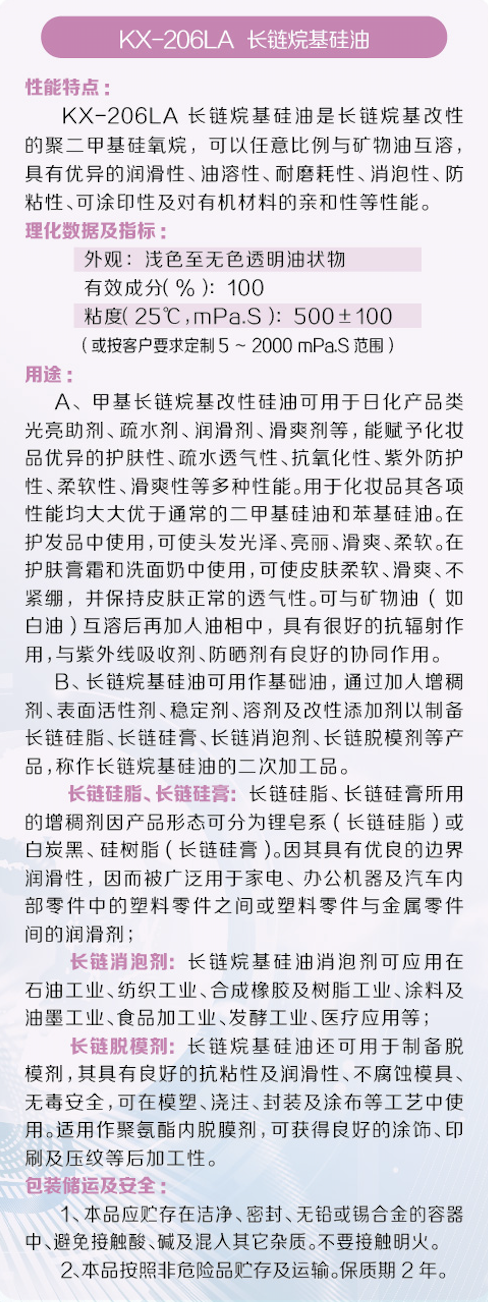

KY-206LA 长链烷基硅油

KY-206LA 长链烷基硅油

Color-changing resin, good effect of discoloring leather, good temperature resistance KY-8587

Color-changing resin, good effect of discoloring leather, good temperature resistance KY-8587