Waterborne polyurethane resin belongs to the technical field of polymer materials, and waterborne polyurethane dispersion (PUD) is a coating and adhesive that uses water as the main solvent.

Polyurethane resin is a high-functional leather treatment agent, but more than 90% of the resin used in the leather factory contains a large amount of organic solvents. Polyurethane resin will cause serious environmental pollution during production and use, and pose health threats to on-site operators. The 18th National Congress of the Communist Party of China proposed that environmental protection, conservation priority, conservation priority, natural development, and low-carbon development should be the focus of future work, to form a spatial pattern, industrial structure, production method, and lifestyle that conserve resources and protect the environment, starting from the source Reverse the deterioration of the ecological environment, create a good production and living environment for the people, and contribute to global ecological security.

The traditional polyurethane resin production process is to prepolymerize polyol and isocyanate for 2-3 hours, then add small molecule chain extender and crosslinking agent for chain extension reaction for 3-4 hours, add a large amount of organic solvent to adjust the viscosity in the middle process , And finally add amines for neutralization. Disperse the adjusted polyurethane polymer in water to obtain an aqueous polyurethane resin emulsion. However, the traditional polyurethane resin production process is relatively long, and more organic solvents are added, which seriously wastes energy during the production process and endangers the personal health of on-site operators.

The water-based polyurethane resin we introduced today has short reaction time, low reaction temperature, and relatively streamlined process, which can effectively save energy and reduce production costs. Use water as organic solvents, instead of the toxic acetone and DMF, which reduces environmental pollution and reduces the hidden dangers of operators. The strength of the waterborne polyurethane resin made by this method is 30Mpa, the elongation rate is 600%, and it has the advantages of high strength and great extensibility. The waterborne polyurethane resin invented by the company’s Kaiyue Technology has the excellent properties of abrasion resistance, solvent resistance, low temperature resistance, and tortuous resistance. It has high solid content, low viscosity, and good stability.

Specific implementation methods We will update the WeChat public account of Huaian Kaiyue Technology Development Co., Ltd.

Electronic packaging leather

Electronic packaging leather

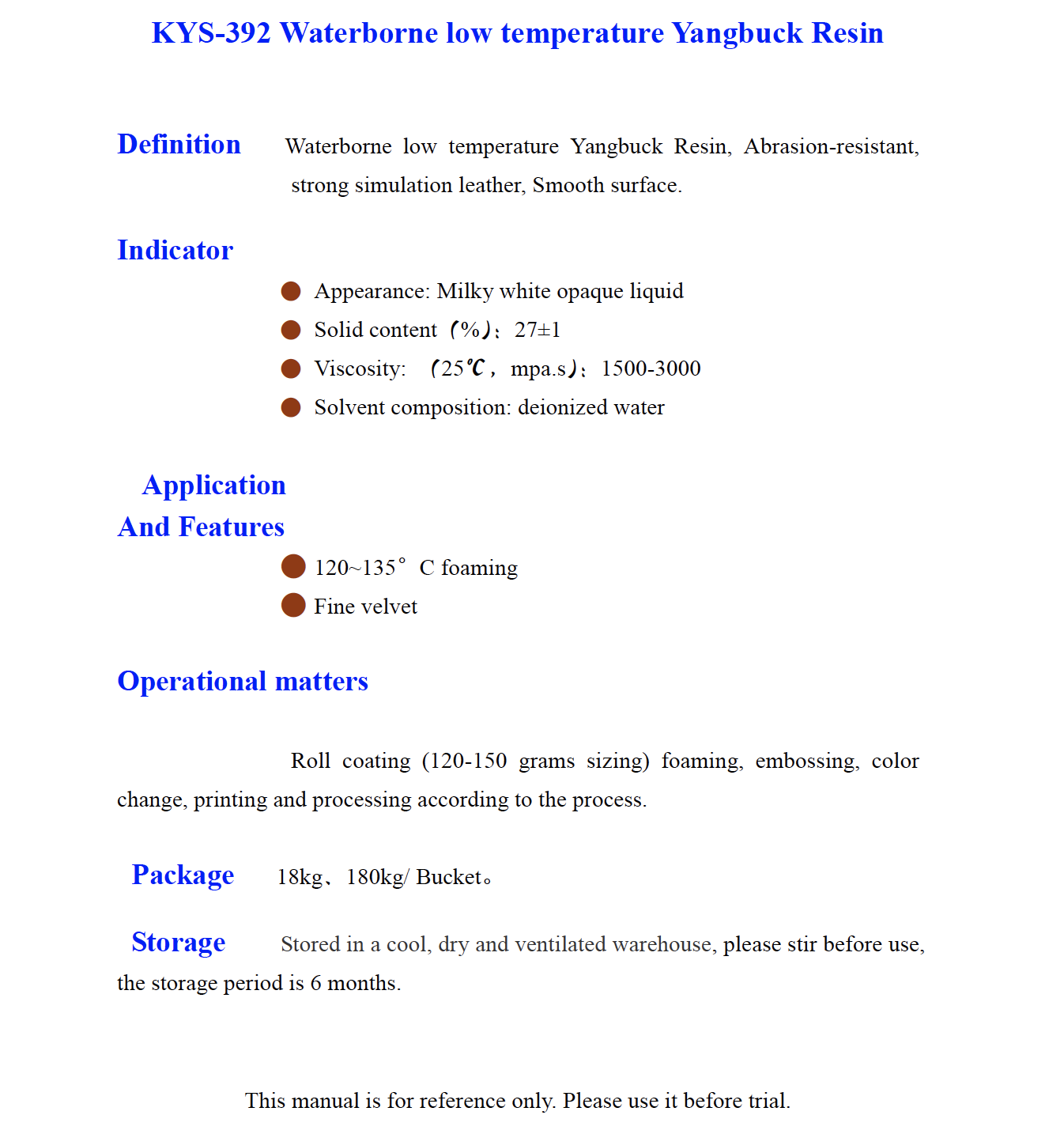

KYS-392 Waterborne low temperature Yangbuck Resin

KYS-392 Waterborne low temperature Yangbuck Resin

水性辊涂亮面树脂

水性辊涂亮面树脂

水性肤感亮面处理剂,改善产品柔软性,防粘

水性肤感亮面处理剂,改善产品柔软性,防粘

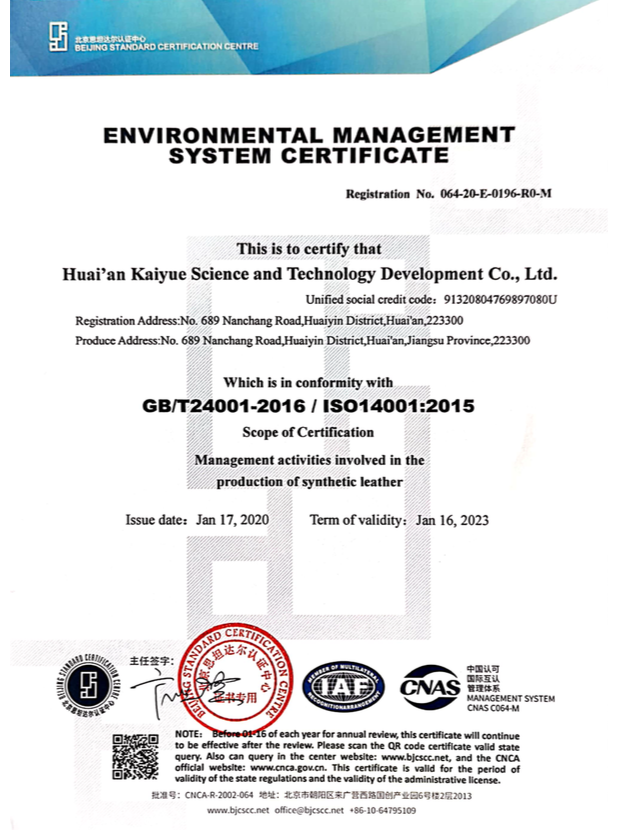

ISO14001:2015

ISO14001:2015

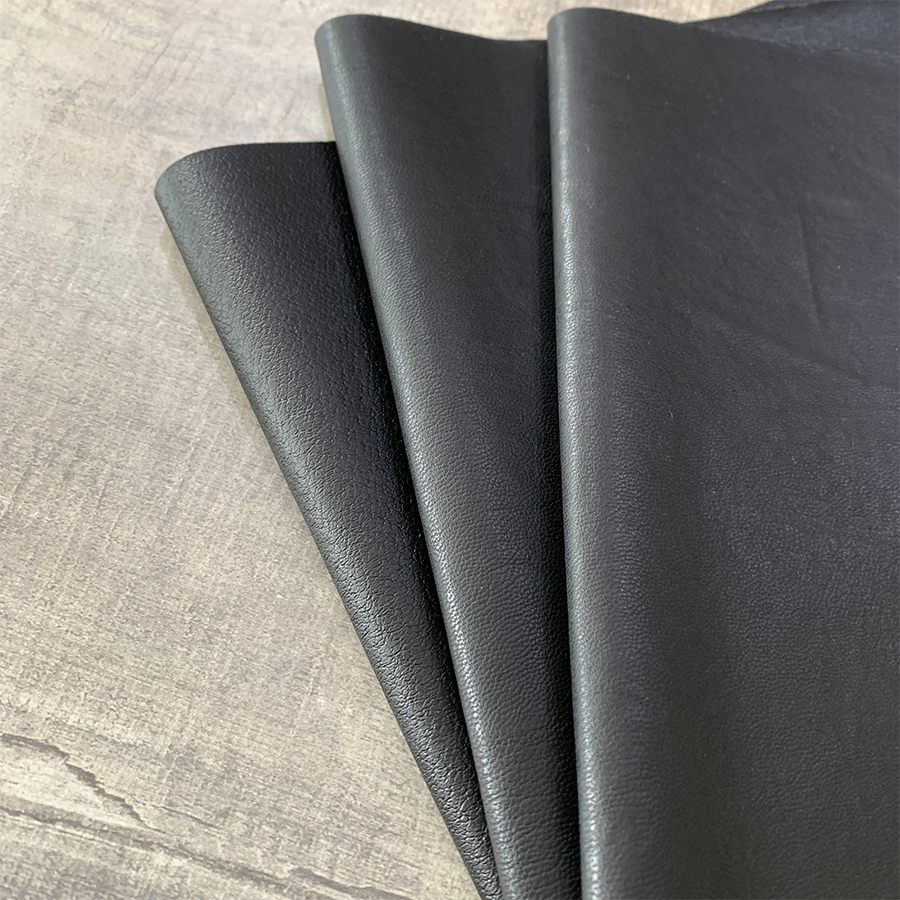

Waterborne PU leather (Crazy Horse)

Waterborne PU leather (Crazy Horse)

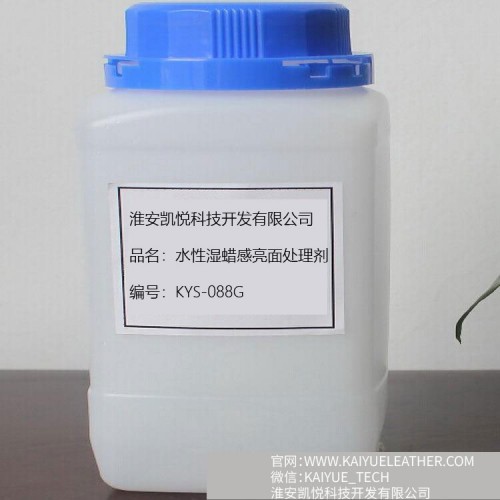

Water-based leather surface treatment agent, Eco-friendly, long-lasting wet wax feel, soft touch, non-slip KYS-088G

Water-based leather surface treatment agent, Eco-friendly, long-lasting wet wax feel, soft touch, non-slip KYS-088G

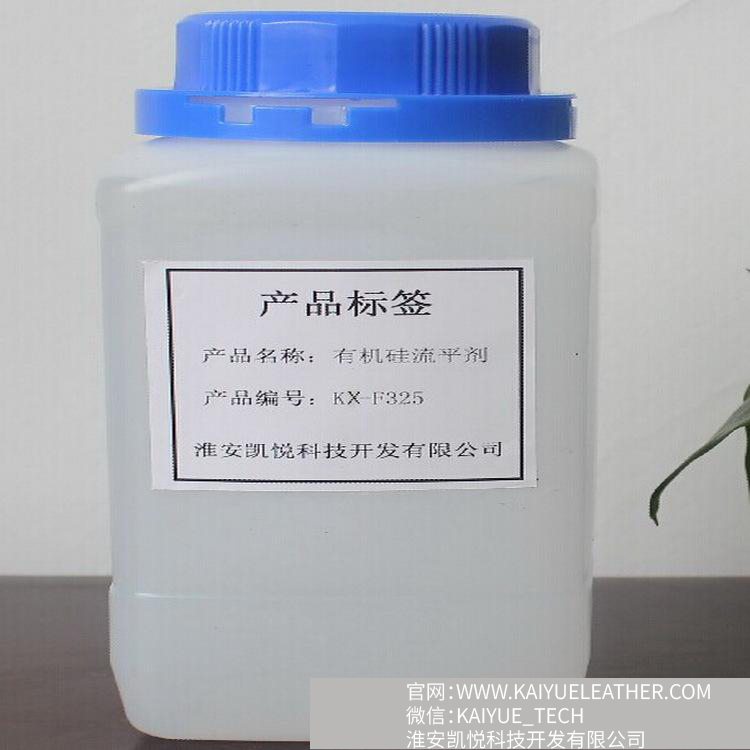

KX-F325 Leveling wetting agent

KX-F325 Leveling wetting agent