What is waterborne microfiber synthetic leather? The following Huai’an Kaiyue Technology Development Co., Ltd. will give you a brief understanding.

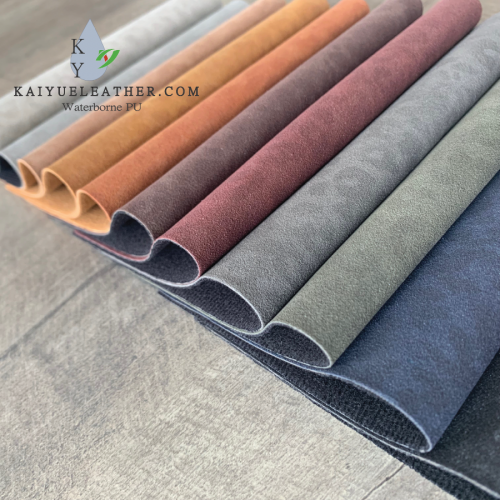

The preparation method is based on the use of flame-retardant automobile ultra-fine fibre polyurethane synthetic leather BASE, supplemented by high-performance non-yellowing water-based polyurethane resin, and adding special protein powder with moisture permeability and scientific processing. Natural leather-touched protein microfiber leather for automobiles. The protein microfiber leather for automobiles prepared by this method has a certain moisture permeability and ventilation effect, which is about 30~70% of natural leather, and the surface has a natural touch similar to natural leather, environmentally friendly and pollution-free, so as to achieve The simulation effect of the leather is closer, even more, durable than natural leather.

Background technique

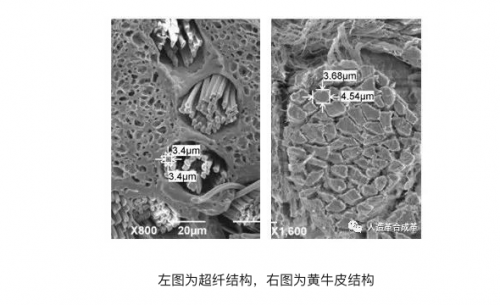

Microfiber synthetic leather is a newly developed high-grade artificial leather, which is developed on the basis of a full analysis of natural leather. Microfibers are made of bundle-shaped microfibers and polyurethane through a special process, with microfibers as the three-dimensional skeleton, and polyurethane has a three-dimensional structure with irregular micropores in the leather. The microstructure of the base fabric is similar to collagen fibres, and it also has similar tissue structure and physical and chemical properties as natural leather.

Microfiber leather has almost all the characteristics and advantages of natural leather and is superior to natural leather in terms of mechanical strength, chemical resistance, uniformity, shape retention, and adaptability to automated cutting. Its lightweight is equivalent to that of the same thickness. In this case, the quality of microfiber leather is about two-thirds of the quality of natural leather for automobiles. If all the microfiber leather is used instead of natural leather, the weight of the whole vehicle can be reduced by I. 5~3kg according to the five-seat calculation. It can save fuel consumption.

However, the ordinary microfiber leather is prepared by the release paper transfer coating method, and the surface layer is made of solvent-based PU resin. During the production of synthetic leather, the resin will form a dense plastic film to make the car microfiber leather The moisture permeability of the base is completely lost, so that the moisture permeability of the entire car’s microfiber leather is almost zero.

In order to solve the problem of loss of moisture permeability and breathability of ordinary automobile microfiber leather, this study added special protein powder to the surface layer, adhesive layer and surface treatment layer of automobile microfiber leather. Wet and breathable properties, added to PU resin, and after ultra-fine dispersion, can be uniformly dispersed into the resin system, so that the prepared automotive microfiber leather also has certain moisture permeability, breathability, and natural leather Similar surface feel.

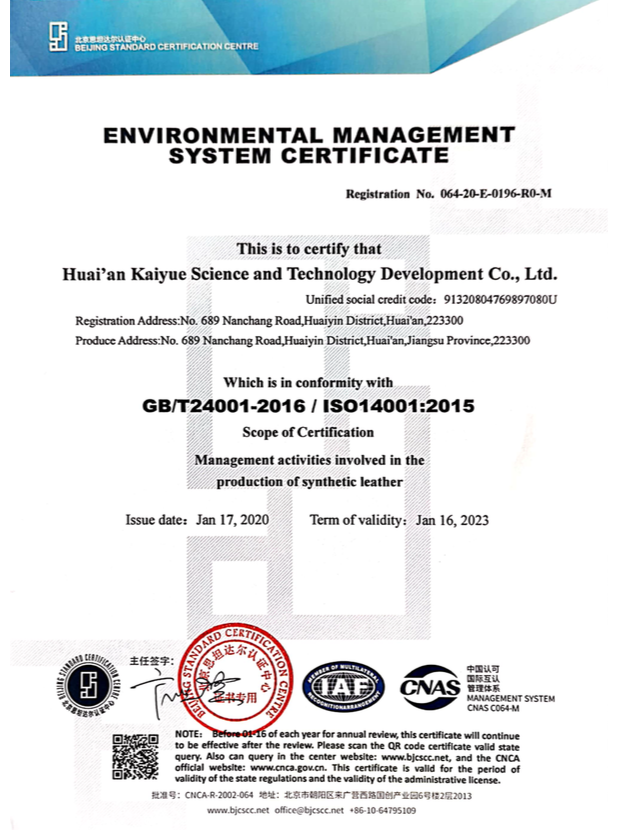

ISO14001:2015

ISO14001:2015

100% Polyester-For Garments

100% Polyester-For Garments

Leather suede matte treatment agent KY-202W

Leather suede matte treatment agent KY-202W

Water-based polyurethane foam is used to produce dry-process water-based synthetic leather

Water-based polyurethane foam is used to produce dry-process water-based synthetic leather

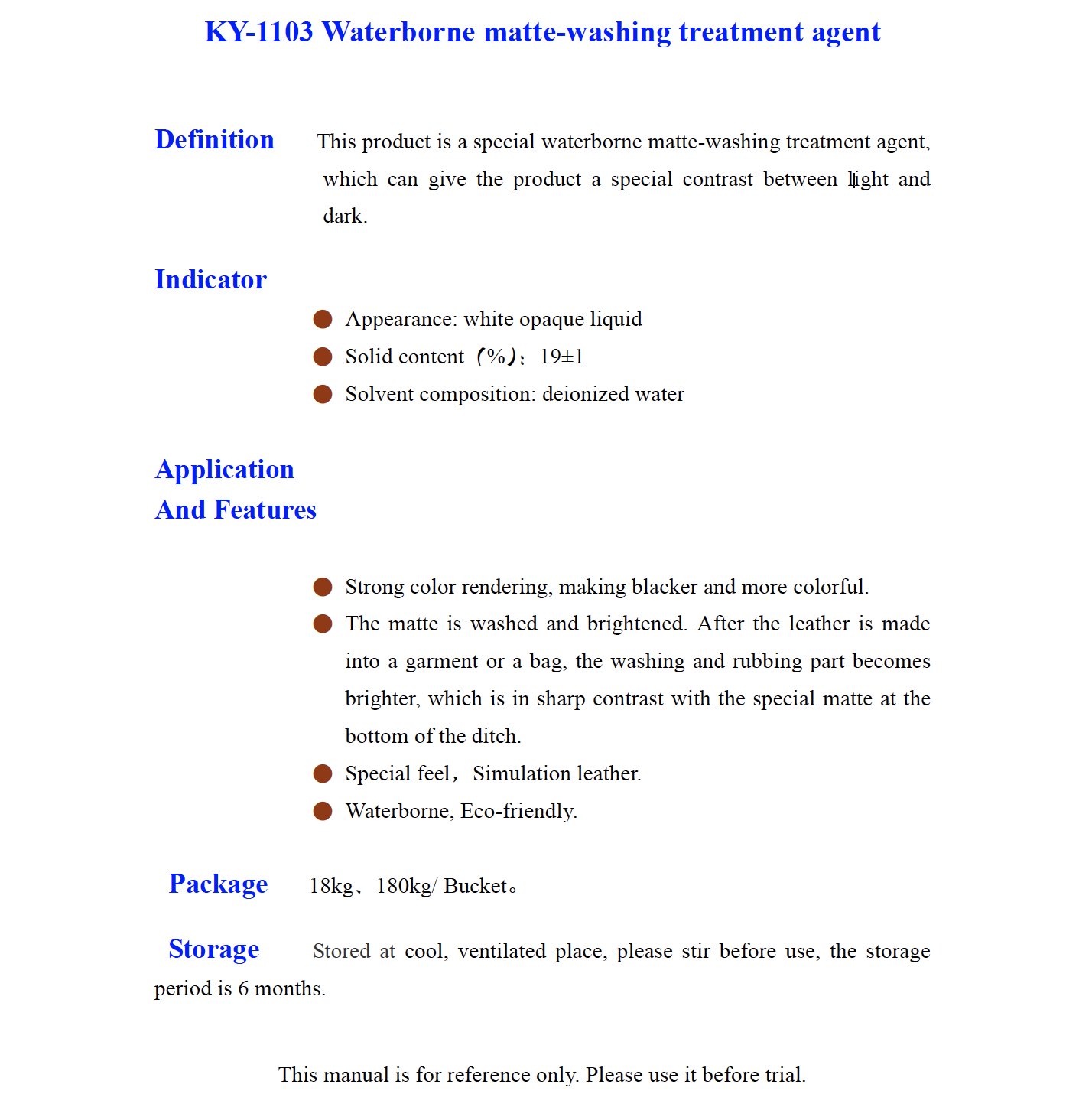

K Y 1103 Waterborne matte washing treatment agent

K Y 1103 Waterborne matte washing treatment agent

Yangbuck

Yangbuck

customization

customization

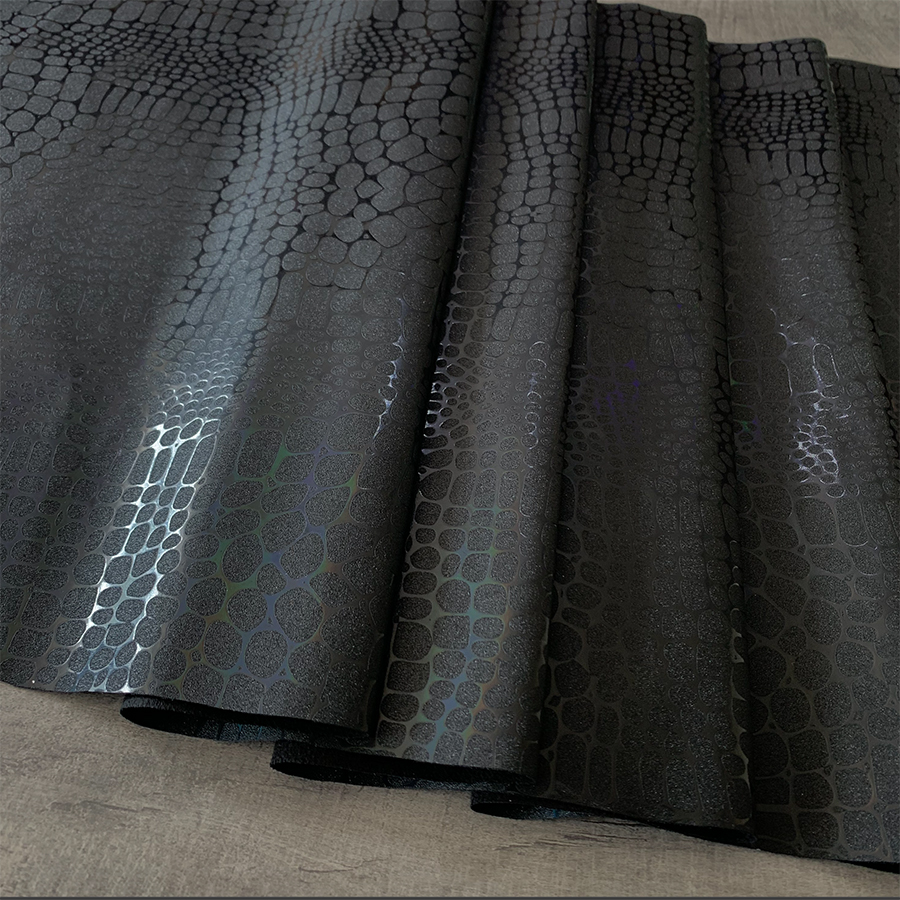

Color-changing resin, good effect of discoloring leather, good temperature resistance KY-8587

Color-changing resin, good effect of discoloring leather, good temperature resistance KY-8587