Water-based environmentally friendly synthetic leather is a synthetic leather made of water-based polyurethane polymer materials. Water is used to replace toxic organic solvents. The production process is pollution-free, green, and does not contain DMF, DOP and other harmful chemicals. It is a replacement for solvent-based synthetic leather. product. Since 2008, the National Development and Reform Commission has listed “water-based synthetic leather and ecological synthetic leather research and development, production and artificial leather, synthetic leather finishing materials technology” as an encouraging development project. Countries such as Europe and the United States have also strictly restricted the content of organic volatile compounds (VOC) in coating systems since 2009, and solvent-based synthetic leather has been restricted from entering the European and American markets.

As the ZDHC (Zero Emissions of Hazardous Chemicals Program) promotes the “Supply Chain Chemical Management Innovation 2020 Action”, well-known global brands are increasingly demanding environmentally friendly synthetic leather. The following is a brief introduction to several silicone additives commonly used in water-based synthetic leather.

1. Wetting and leveling agent

The polysiloxane segments in the silicone molecules can provide very low surface tension. A small amount of polyether-modified silicone can be added to the aqueous slurry to significantly reduce the surface tension of the system, improve the wettability of the slurry and Leveling effect. For the polyether-modified silicone wetting and leveling agent, by adjusting the length of the silicone segment and the polyether segment, and the EO / PO ratio in the polyether segment, good compatibility with aqueous slurry and low foam can be obtained The product.

2. Feel agent

Different silicone additives can give synthetic leather a different feel, such as dry, silky, oily, cottony, shiny, waxy, etc. Due to its own characteristics, water-based environmentally friendly synthetic leather, for example, the slurry used in the production process is basically polyurethane emulsion or dispersion, silicone additives must be stably dispersed in it, compatibility with silicone additives, when added The ease of handling and storage stability after the addition is different from traditional solvent-based synthetic leather, and we should fully consider these conditions when developing.

3. Wear-resistant additives

The lubricity of silicone is a prerequisite for its ability to improve the wear resistance of the coating. The methyl groups in the silicone molecules extend outward, greatly reducing the surface energy of the coating surface. Silicones with high molecular weight and a small number of active groups can produce cross-linking, which has the most obvious effect on improving the wear resistance of the coating. Find a balance between wear resistance and wetting and leveling effects.

4. Defoamer

Due to its structural characteristics, water-based polyurethane slurries are more likely to produce more foam that is not easy to eliminate during the formulation and use process than solvent-based polyurethane slurries. Therefore, it is necessary to add an appropriate defoamer. The emulsion type silicone defoamer prepared with dimethyl silicone oil, fumed silica, and appropriate emulsifier has good defoaming and defoaming effects.

5. Peeling aid

Adding silicone to the top-coating aqueous polyurethane slurry can significantly reduce the surface energy of the coating, reduce the adhesion between the coating and the release paper, help peel off the release paper and the coating, and improve the separation. The number of times the pattern paper is used. For water-based polyurethane slurry, polyether can be used to modify the silicone, so that the silicone has a certain hydrophilicity, so as to maintain better compatibility with the slurry.

6. Reactive silicone

When synthesizing waterborne polyurethane resins, replacing some polyols with modified silicones with double reactive groups that can react with isocyanate groups can improve the physical properties of waterborne polyurethanes, with good leveling, smooth and soft feel, Can also play the role of wear-resistant, breathable.

The company is a manufacturer of water-based polyurethane resin, water-based silicone, water-based synthetic leather, water-based microfibre leather, water-based PU leather.

Huaian Kaiyue Technology Development Co., Ltd. silicone additives

Water-based leather-KY9655

Water-based leather-KY9655

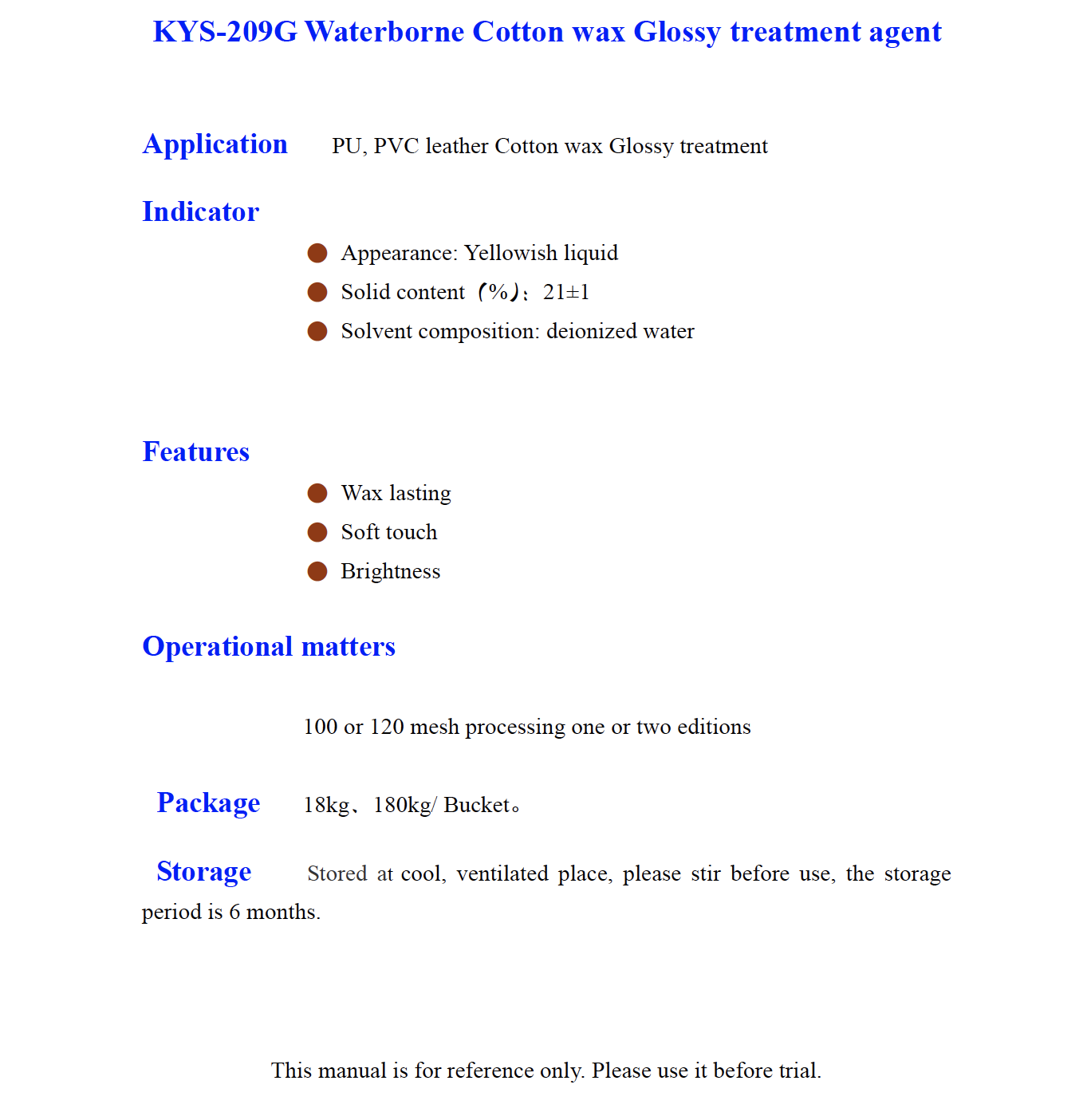

K YS 209G Waterborne Cotton wax Glossy treatment agent

K YS 209G Waterborne Cotton wax Glossy treatment agent

Dermal surface agent, wet waxy matte surface treatment agent KY088S

Dermal surface agent, wet waxy matte surface treatment agent KY088S

Automotive

Automotive

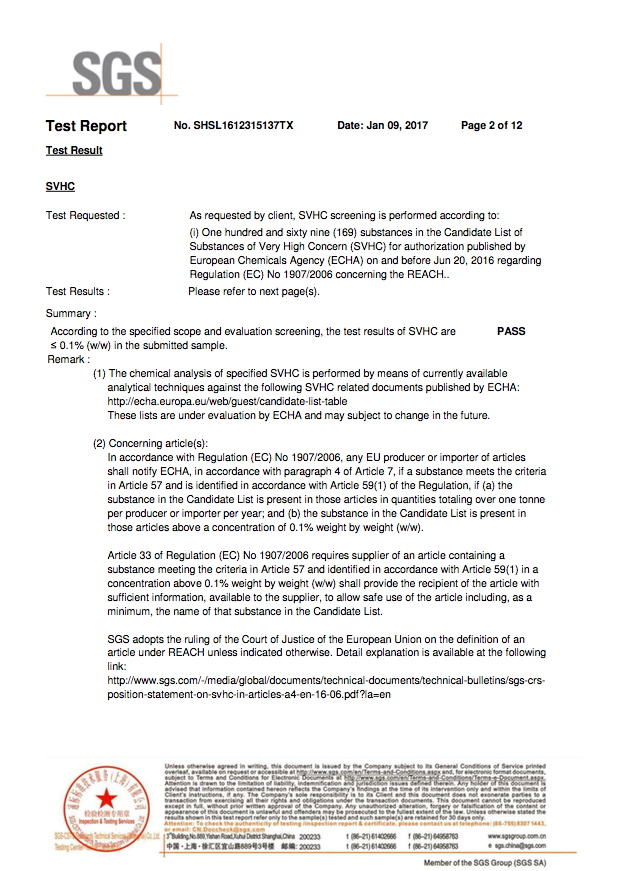

SVHC Test Report

SVHC Test Report

Garment leather washing carbon black treatment agent, higher blackness and oil brightness KY-1877H

Garment leather washing carbon black treatment agent, higher blackness and oil brightness KY-1877H

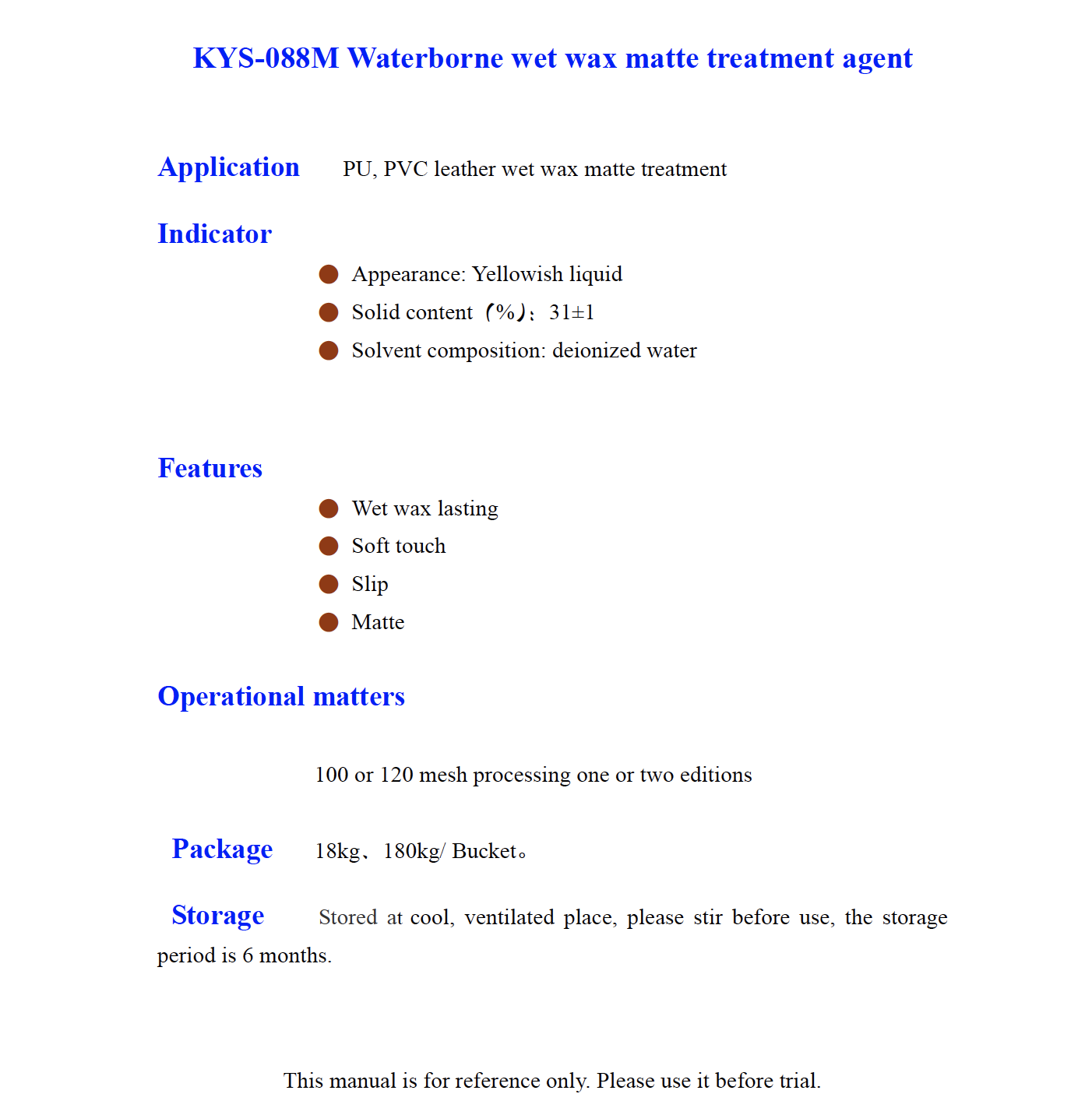

KYS 088M Waterborne wet wax matte treatment agent

KYS 088M Waterborne wet wax matte treatment agent

Water-based leather surface treatment agent Good haze, good leveling, strong velvety feel, good waxy feel DT016

Water-based leather surface treatment agent Good haze, good leveling, strong velvety feel, good waxy feel DT016