The chief engineer of Huai’an Kaiyue Technology Development Co., Ltd. said: Common problems with dry coating are: pinholes on the skin, paper jams, scratches on the surface, color bars, color mishandling, incorrect creases, “fish eyes” , “Orange peel”, pads or application points, pre-peeling and paper leather adhesion, etc.

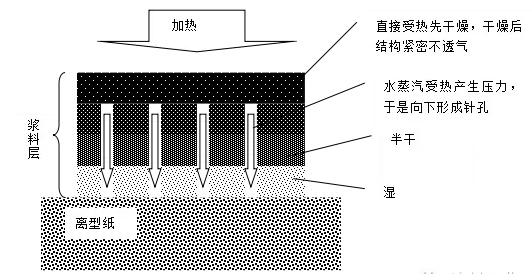

The causes of pinholes on the surface are: the viscosity of the surface layer is too high, the coating is too thick, * the oven temperature is too high, the surface layer has a short drying time, there are too many bubbles in the prepared material, and air is added in the coating tank. Wait. The condition of the slurry during drying is shown in the figure below. Since the thickness of the release paper is much larger than the pulp, this structure is formed before the heat of heating is reached.  When the viscosity of the surface layer is too high, the water vapor generated during drying is not easy to run out of the coating, resulting in small air pockets and pin holes. Reducing the viscosity of the surface layer mixture can solve the pinholes caused by this reason. If the coating is too thick, water vapor is not easy to discharge, which will also cause pinholes. When encountering such problems, the coating thickness should be reduced. If the temperature of the oven is too high, a large amount of water vapor will be generated instantly, and these water vapor cannot be effectively discharged, which will cause pinholes. So * the temperature of the oven cannot be too high. When the surface layer has a short drying time and the surface layer is not completely dried, the slurry of the second layer will affect the discharge of water vapor from the surface layer and cause pinholes. This requires the surface layer slurry to be completely dried before being applied to the second layer. A lot of bubbles in the prepared material is also one of the reasons for the pinholes on the surface. The prepared slurry needs to be left to degas and then used. Adding air into the coating tank will also cause pinholes on the surface. At this time, the coating needs to be added with baffles to fill the material tank.

When the viscosity of the surface layer is too high, the water vapor generated during drying is not easy to run out of the coating, resulting in small air pockets and pin holes. Reducing the viscosity of the surface layer mixture can solve the pinholes caused by this reason. If the coating is too thick, water vapor is not easy to discharge, which will also cause pinholes. When encountering such problems, the coating thickness should be reduced. If the temperature of the oven is too high, a large amount of water vapor will be generated instantly, and these water vapor cannot be effectively discharged, which will cause pinholes. So * the temperature of the oven cannot be too high. When the surface layer has a short drying time and the surface layer is not completely dried, the slurry of the second layer will affect the discharge of water vapor from the surface layer and cause pinholes. This requires the surface layer slurry to be completely dried before being applied to the second layer. A lot of bubbles in the prepared material is also one of the reasons for the pinholes on the surface. The prepared slurry needs to be left to degas and then used. Adding air into the coating tank will also cause pinholes on the surface. At this time, the coating needs to be added with baffles to fill the material tank.

Causes of paper jams are: too small gaps, residues on the paper, paper joints that are too thick or the tape rolled up, improper operation, the edges of the first coating scraper are covered by the second coating to accumulate jams, and there are tapes on the back of the paper Wait. When the coating knife gap is too small, the knife may come into contact with the release paper and jam. So operate according to standard process gaps. Residual debris on the paper can be caught between the paper and the knife, causing paper jams. In this case, the paper inspector should remove debris from the paper in advance. Paper jams can also occur if the paper splices are too thick or the tape is rolled up. Therefore, the paper joint must be straight, and the tape must be tightly pressed flat. Paper jams can also occur when there are sundries such as tape on the back of the paper. In addition to inspecting the surface, check the back of the paper before use. If the edge of the first coating scraper is accumulated by the second coating covering material, the second coating should be used to cover the first coating, and the edge material can be removed with a feeler at any time. Improper operation is also one of the causes of paper jams, so it is necessary to operate according to operating procedures.

The causes of scraping on the surface are: defective scraper blades, debris in the material, dirty filter barrels, dirty scraper equipment such as scrapers, unclean tools, improper use of filters, incorrect mesh counts, and human care Fall into debris and so on. Defective blade of the scraper will lead to uneven feeding, too much or too little local material, resulting in scraping lines. If this happens, the scraper should be repaired or replaced. If there are debris in the material and the filter bucket is not clean, these debris will be caught in the gap between the coating knife and affect the feeding and cause scraping. Therefore, the filtration should be strengthened, and the clean bucket can be used. Similarly, the coating equipment such as the scraper is not clean. If the tools are not clean, the scraping line will be caused. The equipment should be cleaned and the necessary tools must be cleaned. If the filter is used improperly and the number of meshes is incorrect, large particles in the material may get stuck in the gap between the coating knives, causing scratches. Therefore, the scope of use of the filter should be clearly defined when filtering, and the number of meshes should be noted. Of course, accidentally falling into the sundries is also one of the reasons for the wire scraping. This situation should strengthen the responsibility, as soon as there is a drag line, use a feeler gauge smaller than the coating gap.

The reasons for the color difference of the color stripe are: quality problems of raw materials such as color paste and colorants, change in coating amount or unstable vehicle speed, low material level in the trough, no stirring, poor compatibility between the colorant and resin, and poor color Strict carelessness, color difference of ingredients, layering of materials, etc. If it is due to the color difference of raw materials such as color chips or color materials, the material must be strictly controlled. Varying coating levels or unstable vehicle speeds can cause uneven coating thickness, which can cause color differences. Therefore, the coating gap and vehicle speed must be stable. The material level of the trough is too low. If the material is not stirred, the slurry will be uneven and the color bar will be colored. It is necessary to keep the material level during the tanning process. Sometimes the quality of the colorant is not a problem, but poor compatibility with the resin used will cause color streaks. It is necessary to choose a matching colorant or resin. If the color difference caused by the layering of the material needs to pay attention to the viscosity adjustment, strengthen the stirring and feeding. If the color is artificially unscrupulous and unsatisfactory, and the color difference of the color bar caused by the color difference of the ingredients, the technicians and squad leaders should strengthen their responsibilities and strictly control.

Causes the wrong feel and the creases are too large: the resin modulus is not correct, the coating is too thick, the fit is too wet, and the fit pressure is not equal. Modulus is one of the important indicators to measure the feel of resin. The leather feel will be different if the modulus is not correct. Therefore, an appropriate resin modulus should be selected. When the modulus is too high, the hardness of the finished leather is large, and creases are easily generated. At this time, the resin modulus should be reduced. If the coating is too thick, the finished leather can easily be crushed by squeezing. In this case, the coating amount should be reduced. If the bonding is too wet, a large amount of slurry will penetrate into the substrate, making the leather too hard, and easy to produce creases. In this case, the dryness and humidity of the fitting should be adjusted. If the bonding pressure is too large, a large amount of slurry will also penetrate into the substrate, which will cause the hand to be hard.

“Fisheye” is a small circular area. There is no coating agent in this area. “Orange peel” is a slight ripple on the surface of the coating film. The solution is to add leveling additives or reduce viscosity, reduce surface tension and improve wetting. If there are oily hydrophobic substances on the surface or material of the release paper, it will also cause “fish eyes” and “orange peels”. When adding ingredients, choose an additive that does not contain hydrophobic substances. Do not use an ingredient bucket that has been exposed to oily hydrophobic substances. Do not use PVC release paper in the selection of release paper. In short, the choice of ingredients and release paper must be strictly controlled. Padding or coating spots The cause of the bright spots or coating spots is debris on the back of the paper or debris on the coating roller. These impurities can affect the uniformity of the coating, which can cause padding or coating spots. Therefore, it is necessary to remove the sundries on the back of the paper, and the sundries on the coating roller before feeding.

Both of these disadvantages are caused by the poor compatibility of the coating agent with the release paper. The adhesion between the coating agent and the paper is too small to cause pre-peeling, that is, the surface layer film has been detached from the paper during the drying process of the adhesive layer coating agent laminated base cloth (skin), and the corrective method is to mix in the surface layer. Fight some sticky coating agents. The adhesion of the coating agent to the paper is too great, which will cause the peeling resin on the paper surface to fall off or tear the paper torn off. The solution is to add a peeling and anti-adhesion aid to the surface coating agent, and Choose a coating agent that is compatible with release paper. In short, the dry coating production process is a relatively complicated physical and chemical change process, and the problems that occur in actual production are also ever-changing. When dealing with problems, you must find out the reasons before determining solutions and measures to obtain qualified products.

In the dry production of water-based synthetic leather, problems in fitting are often encountered, especially inadequate fitting. This is one of the headaches in the manufacture of synthetic leather. There are generally several reasons for poor bonding: ① Improper resin selection. Generally, the resin used is too soft, which will cause more inadequate bonding; ② the size of the sizing material or the release paper is severely damaged, which results in the lack of local sizing; ③ the resin can not be grasped in the wet and dry state after the machine is loaded Properly, the resin of the adhesive layer is too dry, and the adhesion is not strong; ④After the pressing, the pressure roller is too loose to cause the adhesion to be inadequate; ⑤ The base cloth has been treated with an anti-adhesive agent or a water-repellent agent, etc. The material makes it impossible to adhere. In addition, the water-based resin adhesive must be fully dried to have adhesion, otherwise it will be degummed in contact with water. Especially, under the same conditions, the speed of Bestie is slower than that of oily resin by more than half. Otherwise, because the resin of the bonding layer is not dried, the bottom surface of the synthetic leather will be separated after being water-kneaded.

Using a water-based resin as a bonding layer, especially a soft synthetic leather, will feel too hard. The occurrence of such phenomena generally comes from two reasons: one is that the resin selection is too hard; the other is that the cementation phenomenon is caused by the hardening of the resin. On the one hand, too thin the viscosity of the primer resin will cause bleeding, and on the other hand, too high pressure will cause bleeding or sizing, which must be analyzed separately and comprehensively. This article is an excerpt from “Waterborne Polyurethane Training Course Textbook 2015″.