At the beginning of September each year, China Leather Exhibition (ACLE, also known as Shanghai Leather), co-organized by China Leather Association, the most authoritative service management organization in China’s leather industry, and Asia Pacific Leather Exhibition Co., Ltd., the largest leather exhibition organizer in the Asia-Pacific region. Exhibition) was held in Shanghai New International Expo Center.

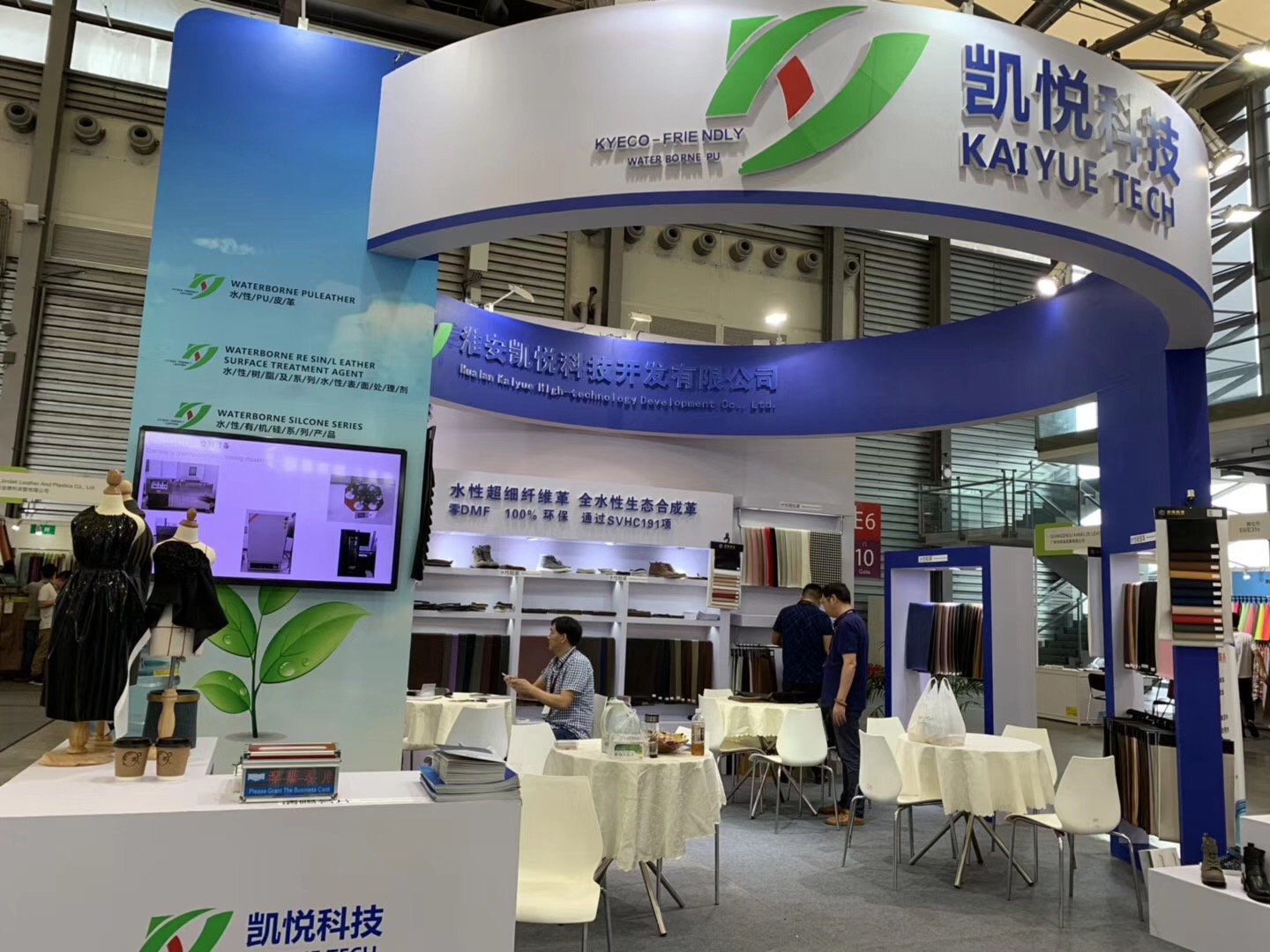

At the exhibition site, KAIYUE TECH has made a series of nearly 100 models of water-based leather for garments, water-based pu leather for shoes, water-based pu leather for sofa, waterborne pu leather for handbag, and waterborne pu leather for packaging. The product performance is the quality of solvent-based products, does not contain harmful chemicals such as DMF, non-toxic and tasteless, and perfectly demonstrates the excellent performance, cutting-edge technology and high-end quality of water-based Polyurethane resin to industry experts, industry elites and many buyers at abroad. .

At present, this technology has been widely used in water-based artificial leather / synthetic leather surface resin, water-based functional resin, water-based imitation microfiber impregnation material, water-based artificial leather / synthetic leather bonding layer resin, water-based artificial leather / synthetic leather surface treatment agent, water-based Artificial leather / synthetic leather foam layer resin, water-based control coating resin, water-based wood lacquer resin and many other fields are closely related to our lives.

At present, there are about 446 synthetic leather factories in China, and there are about 550 in the world, but there are only a dozen water-based synthetic leather factories. The reason why most factories have not been transformed into water-based synthetic leather is that the perception of water-based technology has remained a few years ago, and it is considered that water-based technology is not mature enough. The KAIYUE TECH exhibitors are telling them that the development of water-based technology has advanced by leaps and bounds. The water-based products, production processes and production capacity have matured and can fully meet the current market applications. Through the technology generation and brand influence, the exhibition site, a number of well-known domestic brands and KAIYUE TECH deep negotiations, hope to be able to cooperate in the early days.

As one of the units of China’s synthetic leather green supply chain industry innovation strategic alliance, KAIYUE TECH has been actively involved in the development of the Synthetic Leather Alliance and the development and revision of national and industry standards. By sharing the latest technology and practical results with industry affiliates, Continuously lead the environmental upgrading and transformation of the production management of synthetic leather industry chain. It has successively undertaken the construction of the National and Local Joint Engineering Research Center for water-based synthetic leather manufacturing technology, and has become a Chinese company that has joined the ZDHC program in the synthetic leather industry. While innovating and progressing, it has brought more enterprises to pay attention to and participate in the ZDHC plan to jointly promote the Chinese synthetic leather industry. The development of green environmental protection.

As early as before joining ZDHC, Waterborne KAIYUE TECH has carried out the process technology and equipment of water-based wet synthetic leather bass production line through the technological innovation and upgrading of synthetic leather manufacturing technology. Water-based polyurethane synthetic leather produced by this production line technology and equipment. , without DMF, completely solve the environmental pollution and harm to the human body in the production process of traditional synthetic leather. The products are widely used in the fields of clothing, luggage, shoes, etc., and have become long-term suppliers of many international leading synthetic leather products.

The data shows that a solvent-based synthetic leather production line consumes about 10 tons of solvent-based resin per day, of which more than 60% is organic solvent. The wet synthetic leather production process uses about 85% of the organic solvent, but still remains 15%. . 95% of the organic solvents in the production of dry synthetic leather cannot be recycled. According to incomplete statistics, China’s solvent-based synthetic leather production enterprises use 4 million tons of organic solvents each year, most of which are discharged into the surrounding rivers and air through water and air, which constitutes people’s production, life, environment and life and health. A major threat.

Through the aqueous wet synthetic leather production process, replacing organic solvents with water, without harmful chemicals such as DMF, if the technology is widely used in the synthetic leather industry, the annual consumption of 4 million tons of organic solvents will be saved, and the solvent More than 40% of the coal consumption for DMF recovery in the production of synthetic leather will also be saved, reducing the coal consumption by about 1.6 million tons per year, which greatly promotes environmentally sustainable development.

The development of synthetic leather industry is related to our living environment and affects the physical and mental health of consumers. In the future, KAIYUE TECH will continue to add vitality and motivation to the environmental protection upgrade and green sustainable development of the synthetic leather industry with a more comprehensive industrial layout, deeper technological innovation, more positive development situation and more effective cooperation. At the same time, deepen the innovative research and development and practical application of water-based polymer materials, establish and improve the green standard system for industrial manufacturing, and practice the ambitious goal of “no poison in the world”.