Eco-environmental synthetic leather:

Eco environmental synthetic leather, also known as green synthetic leather, refers to the use of environmentally friendly raw materials, through the clean production process, the formation of functional new polymer fabrics, which is widely used in all aspects of people’s daily life.

Its characteristics lie in saving energy and reducing environmental impact. It can endow the products with new ecological and environmental protection functions, including waterborne polyurethane synthetic leather, solvent-free synthetic leather, superfine fiber synthetic leather, etc. Therefore, the ecology of synthetic leather industry is also the direction of the industry. Its mainstream is the application of environmentally friendly green materials, the promotion of clean process production, the realization of efficient production, consumption reduction and emission reduction, and follow the production mode of circular economy development.

Eco-environmental synthetic leather

Cleaner Production Direction of Environmental Leather:

Eco-synthetic leather must be associated with cleaner production, that is, it will not pollute the environment in the manufacturing process. One is to use water-borne resin instead of solvent-based resin to eliminate organic solvent pollution from the source; the other is to use solvent-free synthetic leather manufacturing technology to achieve cleaner production of synthetic leather.

Waterborne polyurethane synthetic leather is a new technology which can eliminate pollution from the source and make ecological synthetic leather strictly. Waterborne polyurethane is safe and environmentally friendly, without solvent recovery and waste gas generation, and the hand feel, air permeability and moisture permeability of the synthetic leather made of waterborne polyurethane are better than those of solvent polyurethane.

Waterborne resin has good compatibility with traditional mechanical equipment. It does not need large equipment modification and investment and solvent recovery. It is suitable for dry process, wet-process Bess color change, surface and semi-PU leather manufacturing.

Solventless synthetic leather is a new clean production process, which is characterized by liquid raw material transportation, metering, impact mixing, rapid reaction and molding at the same time. In the process of raw material processing, no solvent will be used, no flammable and explosive phenomenon will occur, so no pollution will be caused to the ecological environment. Solventless PU synthetic leather has good mechanical properties, excellent wear resistance and aging resistance.

Water-based rubber plastic mold release agent 40% anionic emulsion KX-495 Kai Xun

Water-based rubber plastic mold release agent 40% anionic emulsion KX-495 Kai Xun

Waterborne PU leather for shoes lining

Waterborne PU leather for shoes lining

Water-based PU-KY9539

Water-based PU-KY9539

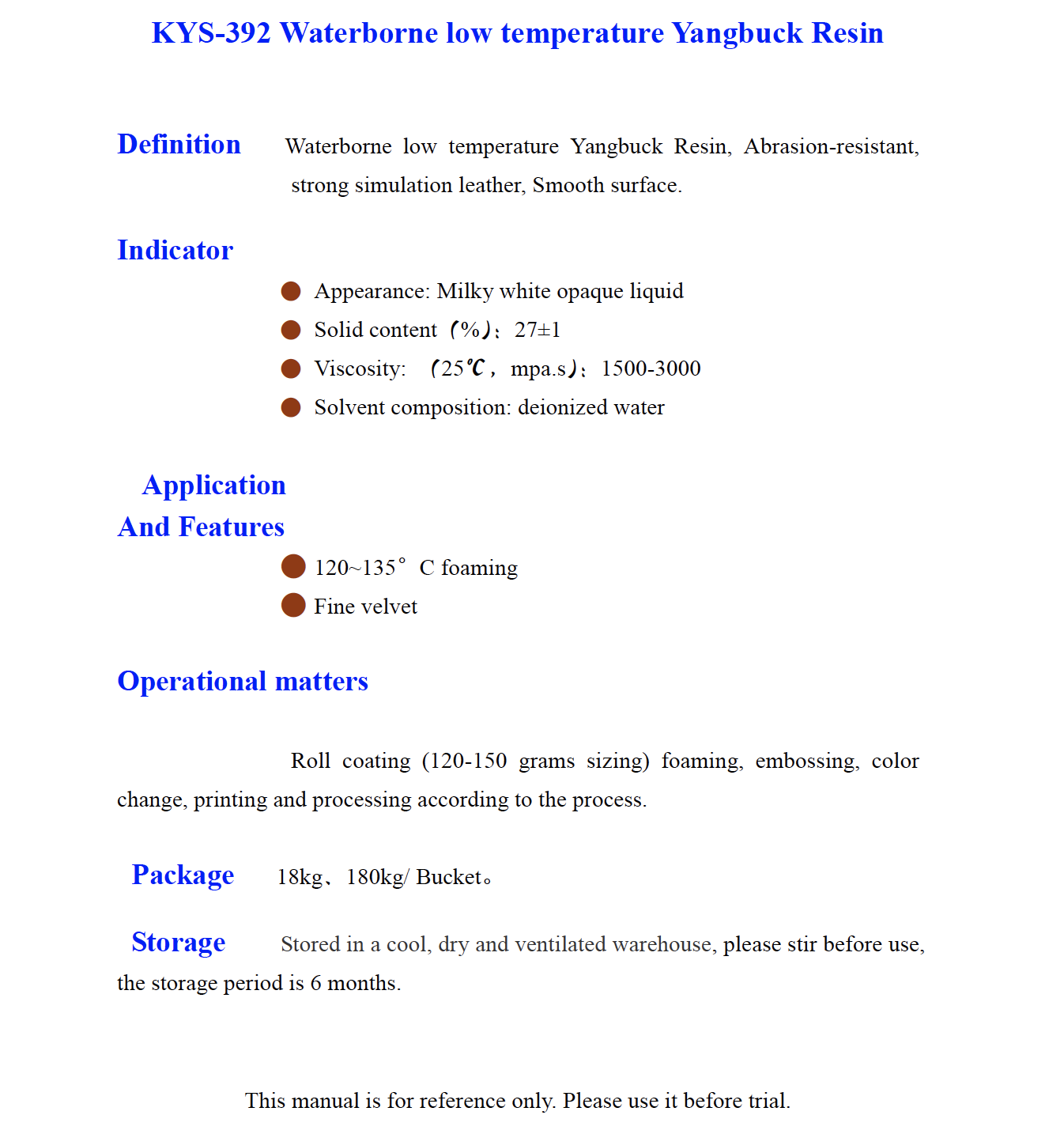

KYS-392 Waterborne low temperature Yangbuck Resin

KYS-392 Waterborne low temperature Yangbuck Resin

simulation leather

simulation leather

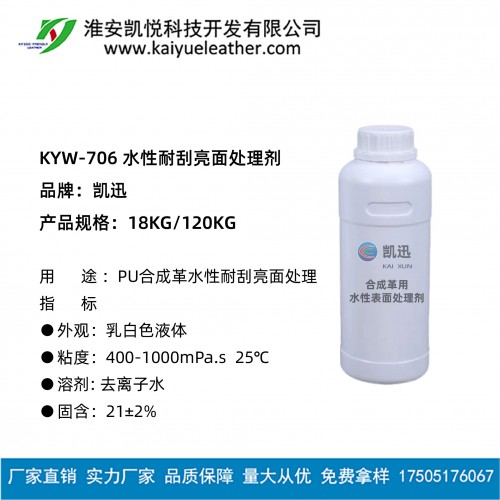

Water-based scratch-resistant matte treatment agent

Water-based scratch-resistant matte treatment agent

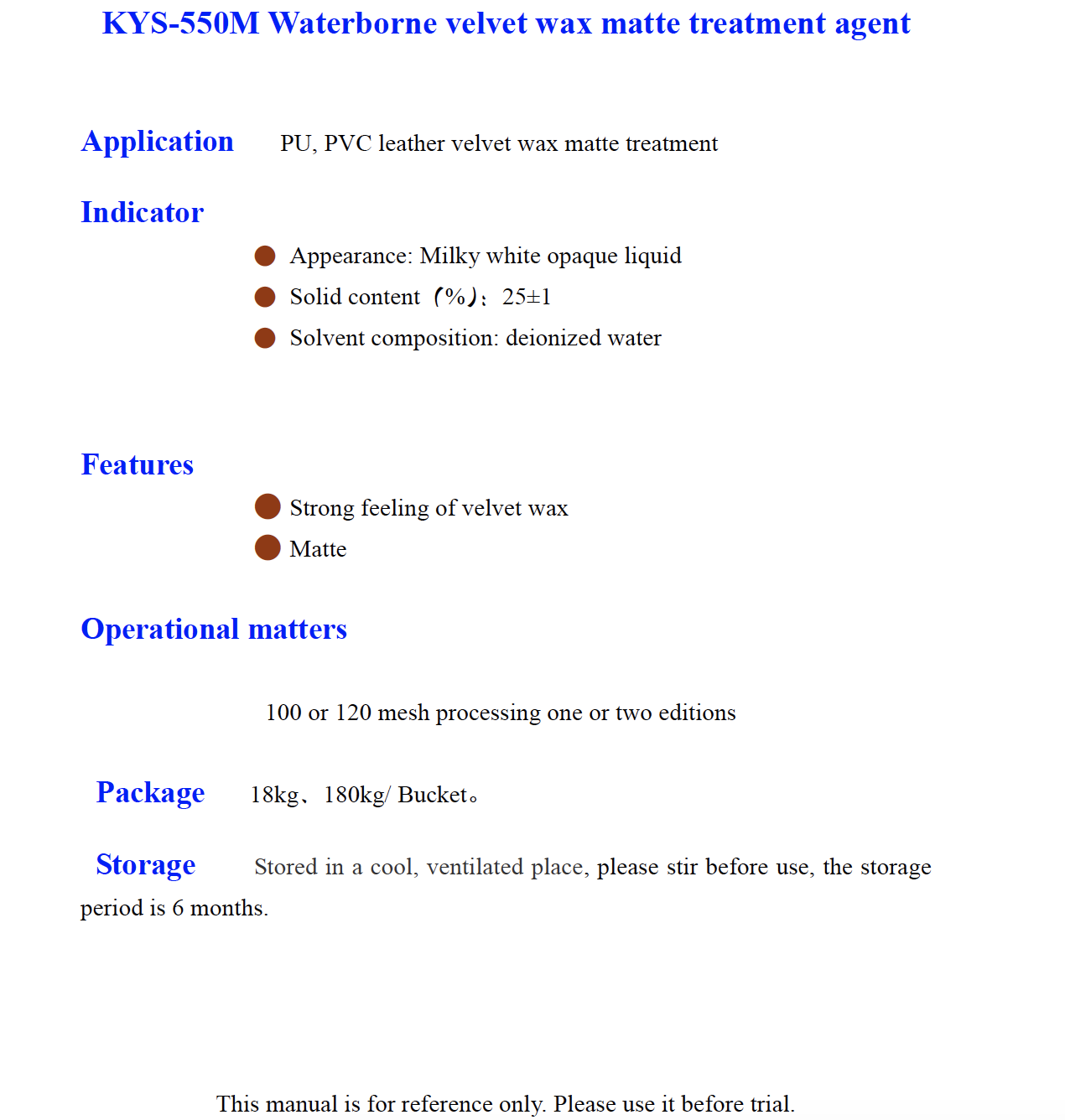

KYS 550M Waterborne velvet wax matte treatment agent

KYS 550M Waterborne velvet wax matte treatment agent

KX-V1100 烷芳基硅油

KX-V1100 烷芳基硅油